Farval

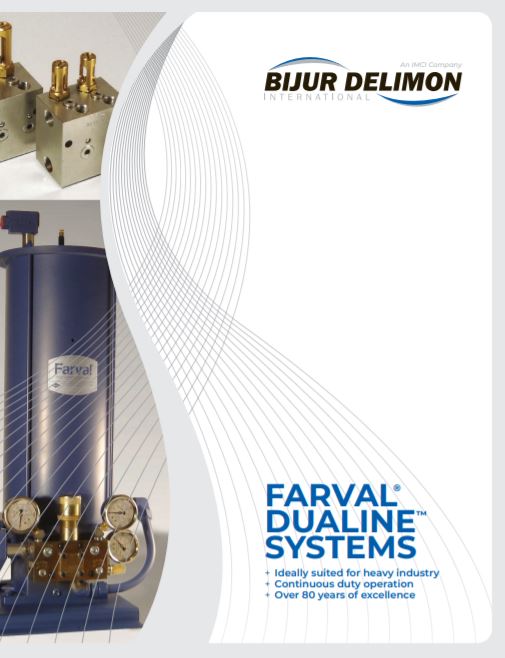

An established leader in heavy-duty lubrication since 1926.

Since its acquisition of Farval® in 1982, Bijur Delimon International has steadily and continually grown and prospered, becoming a focused leader in the field of lubrication and cooling.

Farval® Dualine systems were developed nearly a century ago and are proven to be the best method to deliver heavy greases over long distances. Offering an extensive product line consisting of single-line parallel, progressive, and dual and multi-line lubrication systems. Additional services include the ongoing development, manufacturing and installation of systems, design and applications engineering support, coupled with world-class customer care.

A CLOSER LOOK

View the Farval Dualine® Design Guide for a more in-depth look at planning and designing a dual line system.

Farval

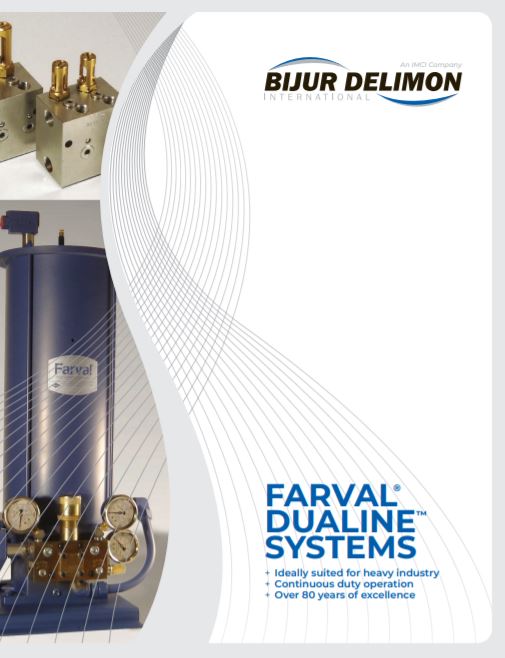

An established leader in heavy-duty lubrication since 1926.

Since its acquisition of Farval in 1982, Bijur Delimon International has steadily and continually grown and prospered, becoming a focused leader in the field of lubrication and cooling.

Farval Dualine systems were developed nearly a century ago and are proven to be the best method to deliver heavy greases over long distances. Offering an extensive product line consisting of single-line parallel, progressive, and dual and multi-line lubrication systems. Additional services include the ongoing development, manufacturing and installation of systems, design and applications engineering support, coupled with world-class customer care.

A CLOSER LOOK

View the Farval Dualine® Design Guide for a more in-depth look at planning and designing a dual line system.

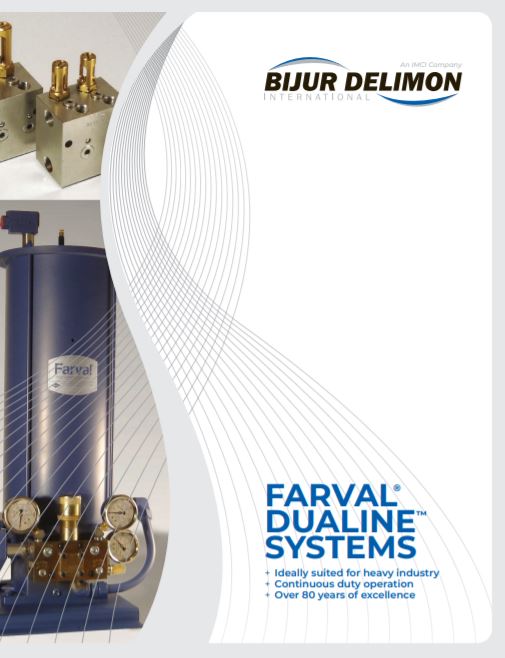

Farval

An established leader in heavy-duty lubrication since 1926.

Since its acquisition of Farval in 1982, Bijur Delimon International has steadily and continually grown and prospered, becoming a focused leader in the field of lubrication and cooling.

Farval Dualine systems were developed nearly a century ago and are proven to be the best method to deliver heavy greases over long distances. Offering an extensive product line consisting of single-line parallel, progressive, and dual and multi-line lubrication systems. Additional services include the ongoing development, manufacturing and installation of systems, design and applications engineering support, coupled with world-class customer care.

A CLOSER LOOK

View the Farval Dualine® Design Guide for a more in-depth look at planning and designing a dual line system.

FARVAL® DUALINE SYSTEMS

Dualine lubricating systems are the ideal solution when continuous duty operation is required. There are several components that are used in designing a Dualine system including valves, central stations, controllers, and lubrication monitors.

GEAR SPRAY SYSTEMS

Gear spray systems are used to lubricate large gear and pinion sets, such as those found in ball mills. Each system includes an air operated pumping station, a measuring valve control panel, a spray nozzle lance, electrical controls, and other optional equipment.