LUBRICATION SOLUTIONS

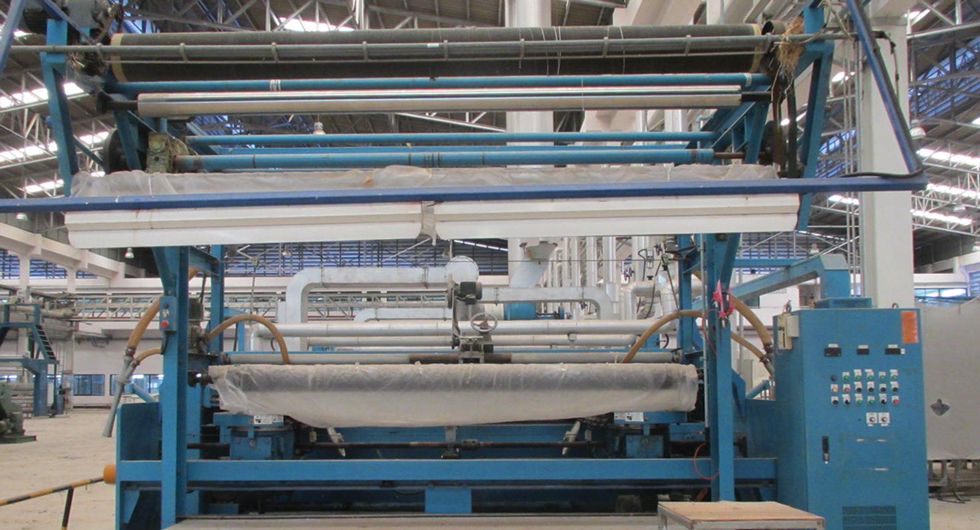

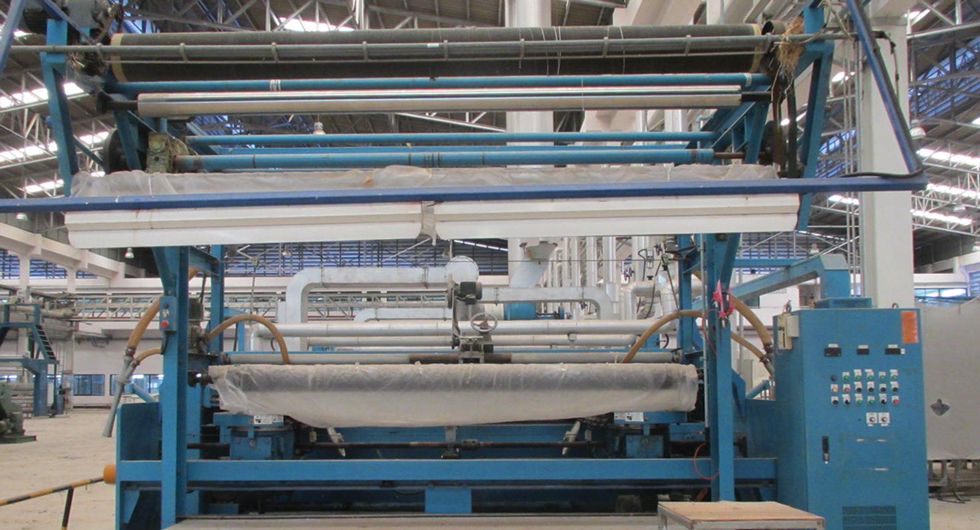

STENTER MACHINES

THE LUBRICATION

SOLUTION FOR

STENTER MACHINES

Stenter machines need precise lubrication to keep them running efficiently and properly. Downtime can be devastating for your company. That’s why Bijur Delimon offers the widest lubrication product offering in the marketplace. With pneumatic, single-point, electric, and manual pumps that work seamlessly with injectors and divider valves, you can deliver a precise amount of lubrication exactly where you want it. With our systems, no sophisticated controls are required. The system fully stands alone with on-board control or ties into your existing controls. Adding a Bijur Delimon system increases equipment life by decreasing wear on vital components and dramatically reduces your lubricant over-consumption.

Need help implementing an automatic system?

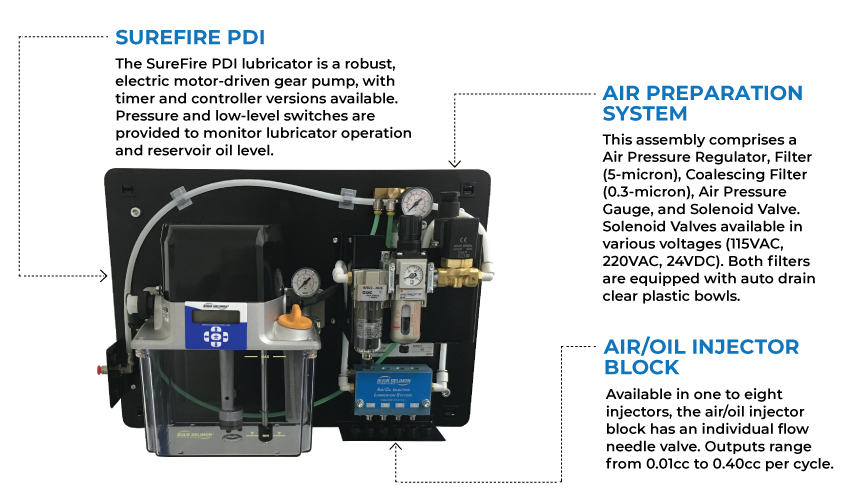

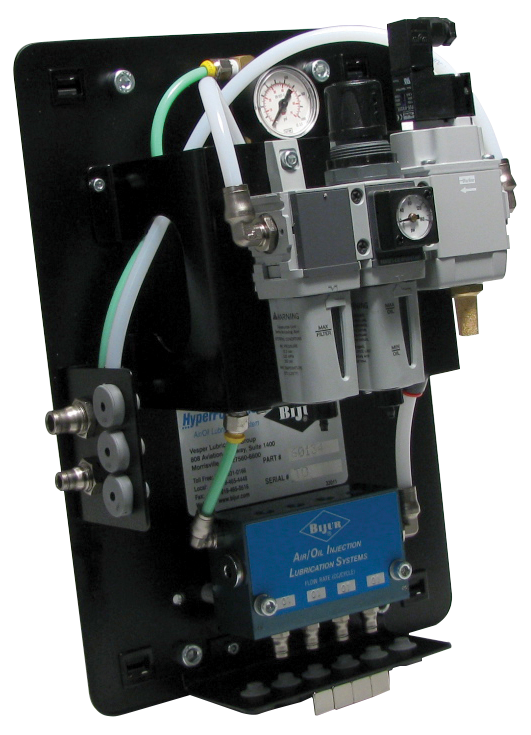

Oil Streak Generator Panel

The Oil Streak Generating Unit delivers high-efficiency lubrication and cooling for high-speed spindles and other surfaces requiring accurate oil deliveries. Air/oil lubrication allows for minimal lubricant delivery on a continuous basis, reducing oil consumption and keeping the bearing surface clean and free of contaminants. The unit can be retrofitted to high frequency spindles designed for mist or air/oil injection systems adn offer value and features found on more expensive systems.

The advanced design delivers precise amounts of lubricant and eliminates residual drift of oil fog or mist during operation.

The unit utilizes a specially designed positive displacement injector (PDI) with oil outputs to a close tolerance level down to 0.01cc/cycle. This permits exact oil volumes to be discharged into an air mixing valve. Controlled air and oil is then discharged through clear plastic tubing to critical bearing points.

A small intermittent discharge form injectors flows along the inside tube wall and stretches out along the length of the tube. Air expansion at nozzle tip delivers controlled spray (not mist) to bearing for optimum performance.