LUBRICATION SOLUTIONS

OFFSHORE WIND

THE LUBRICATION

SOLUTION FOR

OFFSHORE WIND

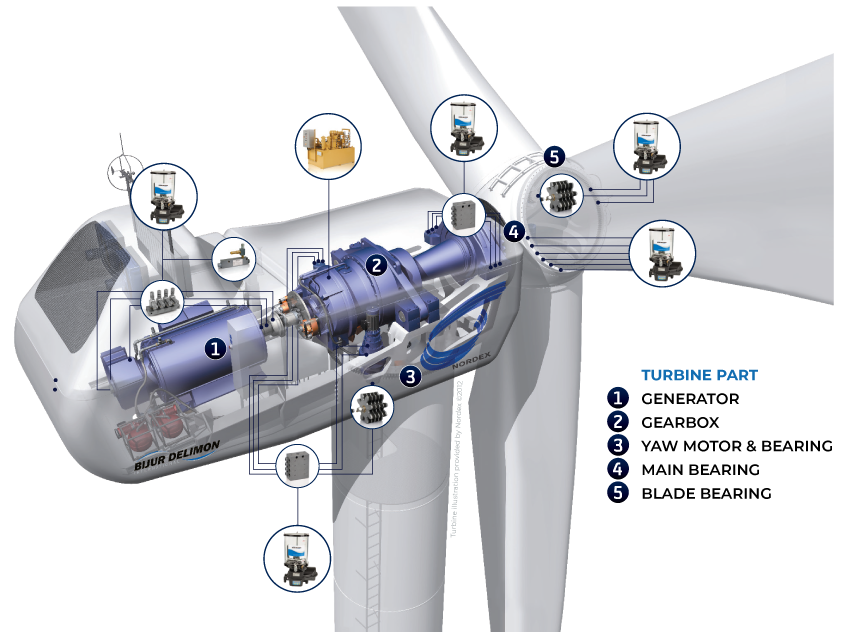

As offshore wind power becomes a more important part of the world energy equation, the need for safety when working on turbines increases. An automatic lubrication system from Bijur Delimon allows for a safer environment in strong winds, rough seas, and difficult locations. The automatic lubrication system is built to increase the time between turbine maintenance visits to eight to twelve months. We have developed a lubricating system kit for use on wind turbines, which is tested as a system before shipment. Many kits include prefilled grease lines and even prefilled reservoirs straight from our factory, helping you to avoid using a substitute grease that is not suitable.

Need help implementing an automatic system?

FEATURES & BENEFITS

PROACTIVE LUBRICATION MAINTENANCE

Wind turbines experience wear and tear from severe environmental factors and structural and mechanical failures, which contribute to the essential need for a proactive lubrication maintenance program. For a reliable wind turbine, many lubrication points are critical to maintain, including the gearbox, generator bearing, open gear, pitch gear, pitch bearing, rotor shaft, yaw bearing, yaw gear, and the hydraulic systems.

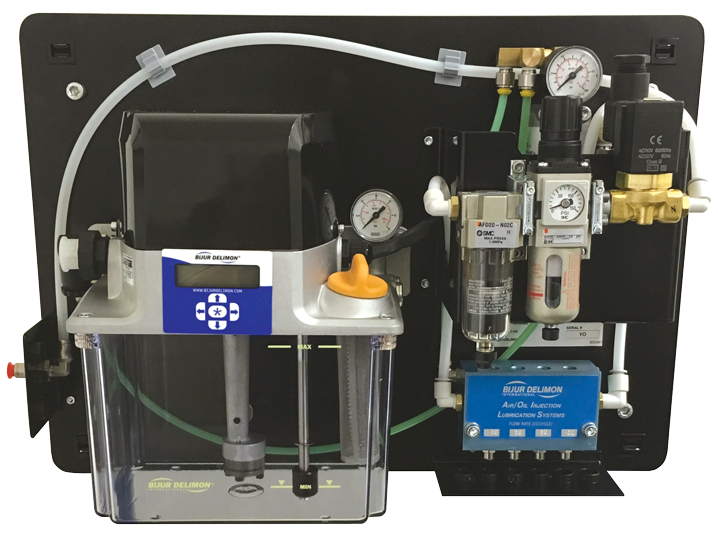

OFFSHORE WIND SYSTEM DESIGN

MultiPort II Lubricator

The MultiPort II Lubricator is an electrically driven multiple outlet lubrication unit design primarily for use with progressive divider valve systems. The unit is capable of housing up to three independent pumping elements for direct feed to lubrication points or through a distribution network of progressive divider valves. These lubricators are available with 24 VDC motors which make them ideal for use in mobile applications. An integral controller is available, or the pump can be controlled by an external controller (such as our SMDC) or by the customer's PLC/DCS/etc.

PVBM Progressive Divider Valve

PVB Mobile Divider Valves accurately meter and dispense lubricant to as many as 20 outlet lines at operating pressures up to 3600 psi (248 bar). Output volumes are fixed at 0.17cc (0.01 cu. in.) per cycle but can be combined with other outlets by using appropriate fittings for larger outputs. Valves are available with cycle indicator pins to provide visual confirmation of system operation. In addition the cycle pin can be fitted with a switch to provide electrical feedback to a system controller.