LUBRICATION SOLUTIONS

FIRE APPARATUS

THE LUBRICATION

SOLUTION FOR

FIRE APPARATUS

Whether you own or lease the equipment, proper maintenance pays off for everyone. The most common bearing failure is a damaged grease seal due to over pressurization while manually greasing. An automatic lubrication system minimizes pressure and provides metered grease to all points while your equipment is in operation. When all bearings are properly lubricated, you can expect an extended service life of your equipment and avoid unexpected costly repairs and downtime. Tired of crawling under or over equipment to service hard-to-reach lubrication points? Our automatic system takes care of the work for you.

Need help implementing an automatic system?

FIRE APPARATUS

SYSTEM DESIGN

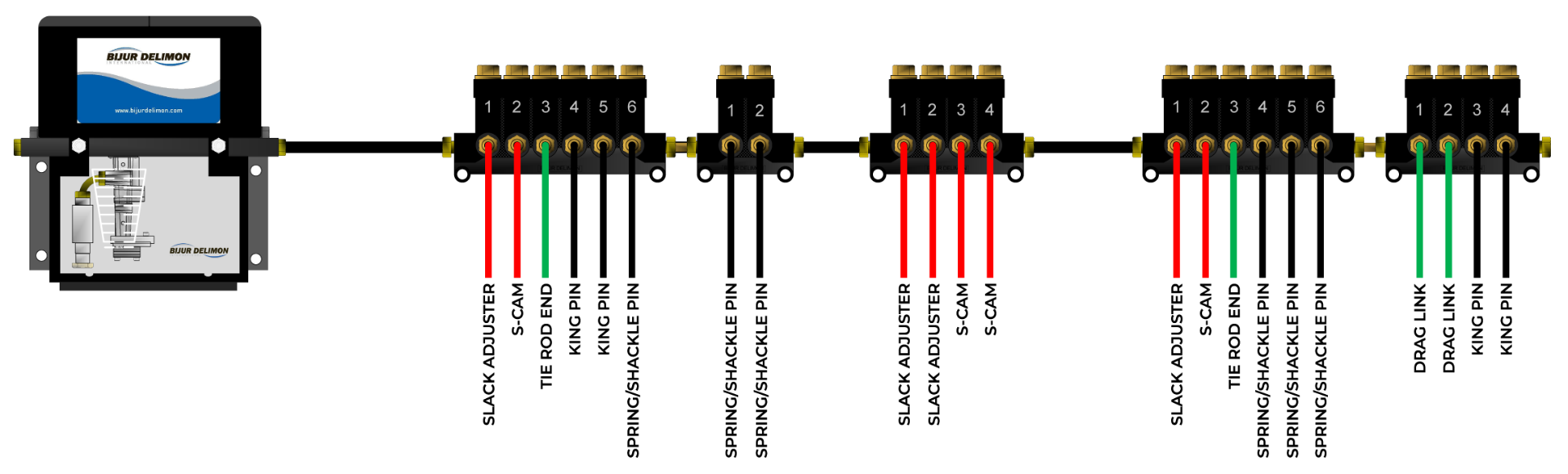

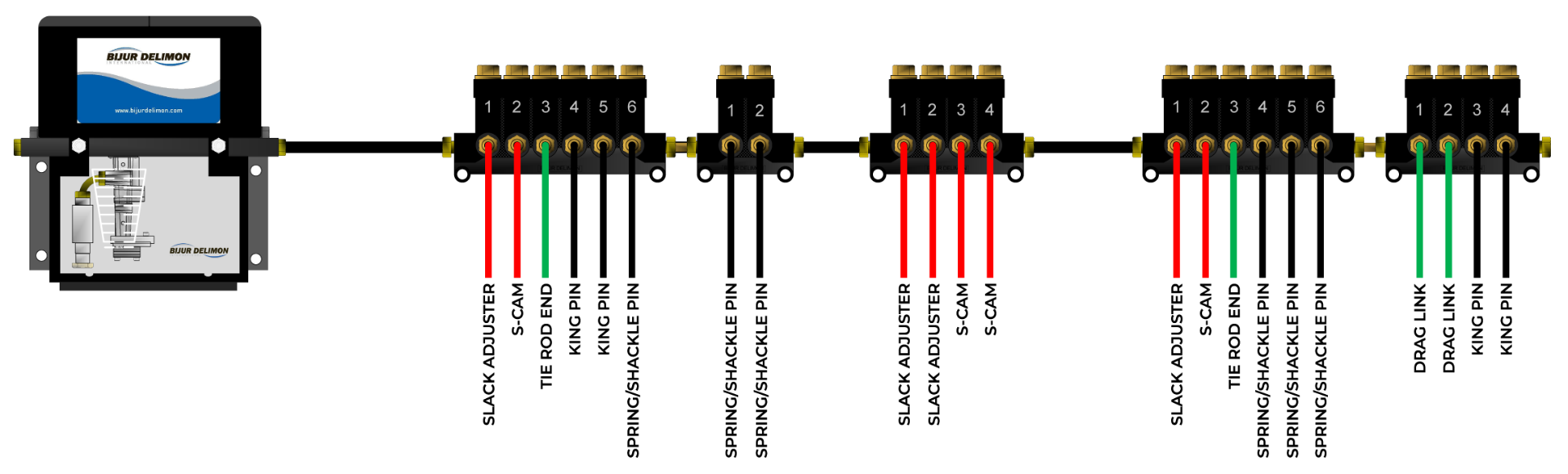

FIRE APPARATUS SYSTEM DESIGN

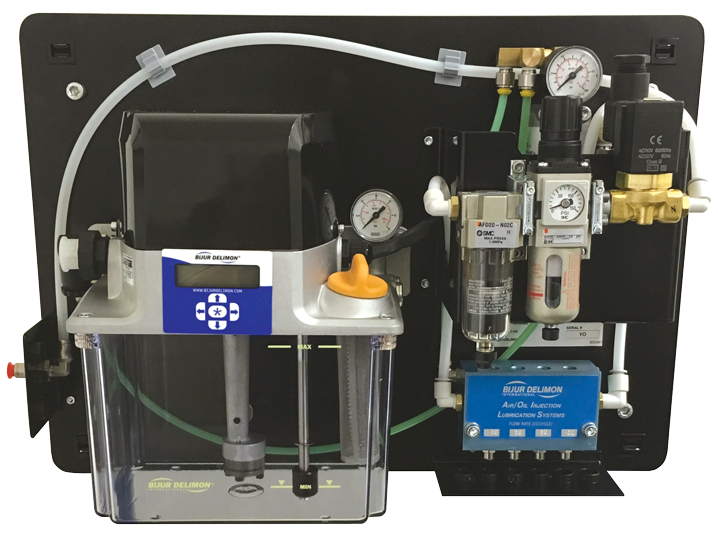

BL3 Lubricator

The BL Lubricator is a motor driven gear pump available with either a 12 or 24 VDC motor. These lubricators are fitted to 3 liter reservoirs and are designed primarily for use with mobile equipment. BL Lubricators are normally used in conjunction with VXLO Indirect Injectors mounted throughout the distribution network. Multiple points of lubrication can be achieved with this gear pump using NLGI grade 00 and NLGI grade 000 greases.

SMDC Controller

The SMDC Mobile Controller is a multi-purpose programmable controller used with on-board mobile lubrication systems. The unit is energized by the vehicle or machine’s ignition switch. Controller settings are saved whenever power is interrupted. Up to four operating modes can be selected which allows the controller to be used with various lubrication system designs. A voltage selector switch is located inside the enclosure for both 12 and 24 VDC service.

VXLO Injectors

The VXLO Injector meters and displaces positive volumes of lubricant to individual lubrication points. Each injector in a system is independent of each other. The volume displaced by each injector is controlled by the interchangeable metering screws. These injectors are indirect feed (post fire injectors), discharging lubricant to the lubrication point via spring force when mainline pressure is relieved. The total volume of lubricant fed to each point is dependent on the metering screw rate and the cycle frequency of the lubricator.