Lubrication Solutions

for Cement

Cement plants must endure freezing cold and sweltering heat - sometimes within mere months of each other. Despite such extreme conditions, machinery and equipment used at cement plants must operate effectively, efficiently, safely, and smoothly. Making sure that your cement equipment is properly lubricated is a good start.

Bijur Delimon designs, develops and delivers high-performing, low-maintenance, cost-effective automatic lubrication systems that effortlessly handle the demanding and challenging conditions of the cement industry. Our lubrication systems for the cement industry deliver precise, uniform amounts of lubrication to reduce friction and wear, protect key components against corrosion, dissipate heat, and keep your machinery functioning at a high level.

What's New in Cement Lubrication

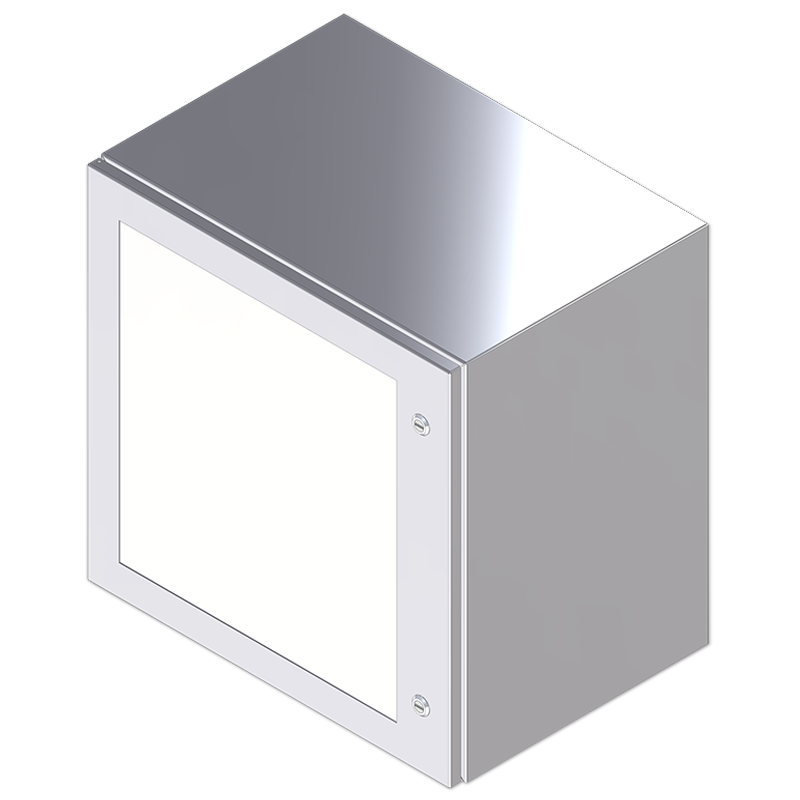

ENCLOSURES

Protect your lubrication system from the harsh environment it operates in with enclosures.

Custom enclosures and panels protect your system and include assembly of your system allowing for "plug-and-play" installation. Enclosures protect the mechanical and electrical components from dust, dirt, oil, water, and other contaminants.

FEATURES & BENEFITS

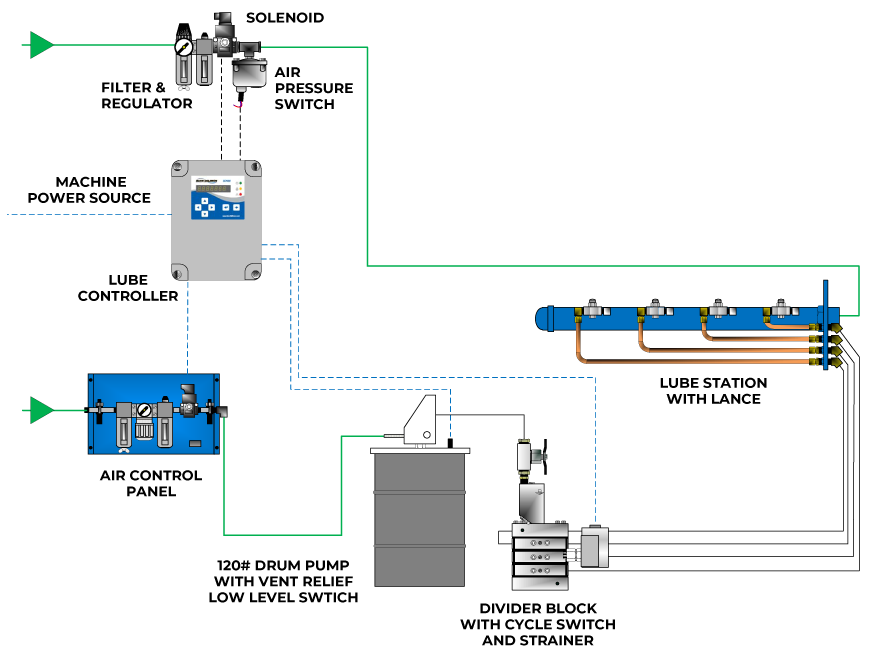

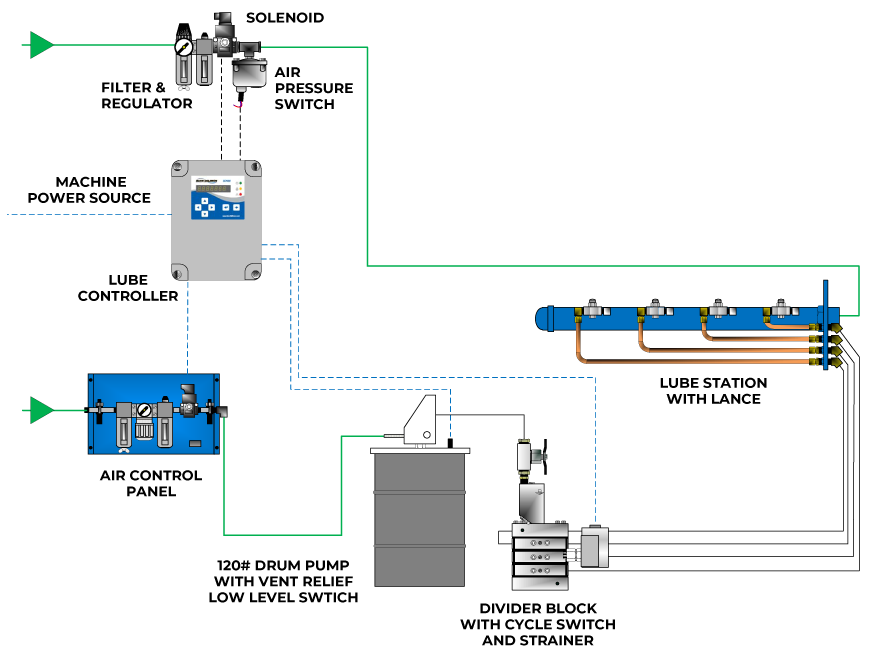

SYSTEM OVERVIEW

Bijur Delimon gear spray systems are used to lubricate large gear and pinion sets such as those found in kilns. Each system includes an air operated pumping station, a measuring valve control panel, a spray nozzle lance, electrical controls, and other optional equipment.

Gear face widths of 2" to 42" can be lubricated with nozzles and nozzle spacing designed accordingly. Because our gear spray systems operate intermittently they can be thought of as film maintaining devices. The electrical controls provide broad cycling flexibility, as well as fault monitoring and afterblow to purge nozzles.

CEMENT PLANT SYSTEM DESIGN

CEMENT PLANT SYSTEM DESIGN

M2500G Divider Valve

M2500G Series Divider Valve Manifolds are the principal components of a progressive lubricating system. Modular construction makes these blocks easy to install, modify and maintain, without removing any tubing. The Zinc-Nickel plated steel body ensures longer life in nasty environments.

Spray Lance

Spray systems are used to lubricate large gear and pinion sets, found on ball mills, rod mills, kilns, etc. Each systems includes an air operated pumping station, a measuring valve panel, a spray nozzle, electrical controls, and a number of optional features. Gear face widths of 2" to 42" can be lubricated with nozzles and nozzle spacing designed accordingly. Since Bijur Delimon gear spray systems operate intermittently they can be thought of as film maintaining devices. The electrical controls provide broad cycling flexibility as well as fault monitoring and after blow to purge the nozzles.

Barrel Pump

Air-operated barrel pumps are used where medium to heavy duty service conditions exist and rapid build-up of lubricating system pressure is desired in either air-operated central stations or bulk transfer of lubricants. These pumps are normally used to transfer lubricants from original refinery drums to the reservoirs on central lubrication systems.

Enclosures

Enclosures are designed to house and product mechanical and electronic components from harsh environments, for use in installations where dust, dirt, oil, water, or other contaminants are present. All enclosures include subpanels and assembly of your system mounted inside the enclosure.

Oil Circulating Systems

Bijur Delimon design and support teams work closely with customers to ensure our Oil Circulating Systems achieve the system performance levels required. We pride ourselves on our ability to deliver the complete engineered design solution. Using the latest CAD technology and 3D modeling, our designers ensure all specifics are met with precision without ever compromising the systems efficiency or the manufacturing process. With over 70 years of experience, our dedicated team will work with you from concept to completion.

Providing the products you need

Our automatic lubrication systems are expertly designed, skillfully crafted and rigidly tested. Our experts will work closely with you to ensure our system meets your exacting lubrication requirements.

Our systems are easy to install - only the lance or nozzles need to be mounted before they can started delivering the lubrication your machinery need.

For the cement industry, Bijur Delimon supplies automatic lubrication systems for:

- Conveyor Bearings

- Electric Motors

- Gearboxes

- Idlers

- Open Gears

- Pinion & Bull Gears

- Rotary Kilns

We offer an extensive line of products for use in the cement industry, including:

M2500G Valve

- Progressive lubricating system

- Modular construction

- Easy to install, modify and maintain

- Zinc-Nickel plated steel body construction

- Durable and reliable

Spray Lance System

- Lubricates large gear and pinion sets

- Air operated pumping station

- Measuring valve panel

- Spray nozzle

- Electrical controls

Barrel Pump

- Transfers lubricants from refinery drums to reservoirs

- Ideal for medium to heavy-duty service conditions

- Air operated

Delivering the service you deserve

For almost a century, Bijur Delimon has been the global leader in automatic lubrication systems.

We have the expertise, the equipment, and the experience to provide high-quality, long-lasting lubrication solutions that improve your productivity, reduce your downtime, and enhance your profitability.

We are your perfect lubrication partner.

Expertise

- Automatic lubrication systems are all we do – we are truly the specialists in the field and the best in the business.

- We have engineering, manufacturing and sales operations well-positioned on three continents, with facilities in the United States, China, France, Germany, the United Kingdom, Austria, Ireland, India, and Spain.

Equipment

- We offer an extensive line of products for use in a wide variety of industries, including heavy-duty grease systems, oil recirculating systems, light and heavy-duty oil systems, mobile on- and off-road fluid grease applicators, single point feeders, and cooling and chilling units.

Experience

- Our dedicated, knowledgeable regional sales managers work closely with you to determine, select and supply the lubrication system that best fits your needs.

Keep your equipment running efficiently during the most critical time of the year.

Keep your equipment running efficiently during the most critical time of the year.