Oil Circulating Lubrication Systems (OCS)

Bijur Delimon design and support teams work closely with customers to ensure our Oil Circulating Systems achieve the system performance levels required. We pride ourselves on our ability to deliver the complete engineered design solution. Using the latest CAD technology and 3D modeling, our designers ensure all specifics are met with precision without ever compromising the systems efficiency or the manufacturing process. With over 70 years of experience, our dedicated team will work with you from concept to completion.

Fill out our form to design

an oil circulating system.

OIL

CIRCULATING

PRODUCTS

View our oil circulation product offering.

DESIGN OF SYSTEMS

Bijur Delimon has recognized that the reliability and efficiency of a successful Oil Recirculation System requires it to fulfill the following key functions:

LUBRICATION

Supplying the appropriate quantity of lubricant of the required viscosity, temperature and pressure to a bearing or gear train to prevent failure.

COOLING

By maintaining the system oil temperature and flow rate at the required parameters, the heat generated by the motion and load of bearings and gear trains is removed, ensuring that lubrication is provided at the optimum performance level.

FILTRATION

It is critical to remove contaminants, such as dust, wear particles, water, and other extraneous materials that build up during the operation of bearings and gear trains. The lubricant needs to be continually filtered to the correct cleanliness level prior to being recirculated.

Bijur Delimon Design and Support Teams work closely with customers, component suppliers and lubricant manufacturers to ensure our Oil Recirculation Systems achieve the system performance levels required.

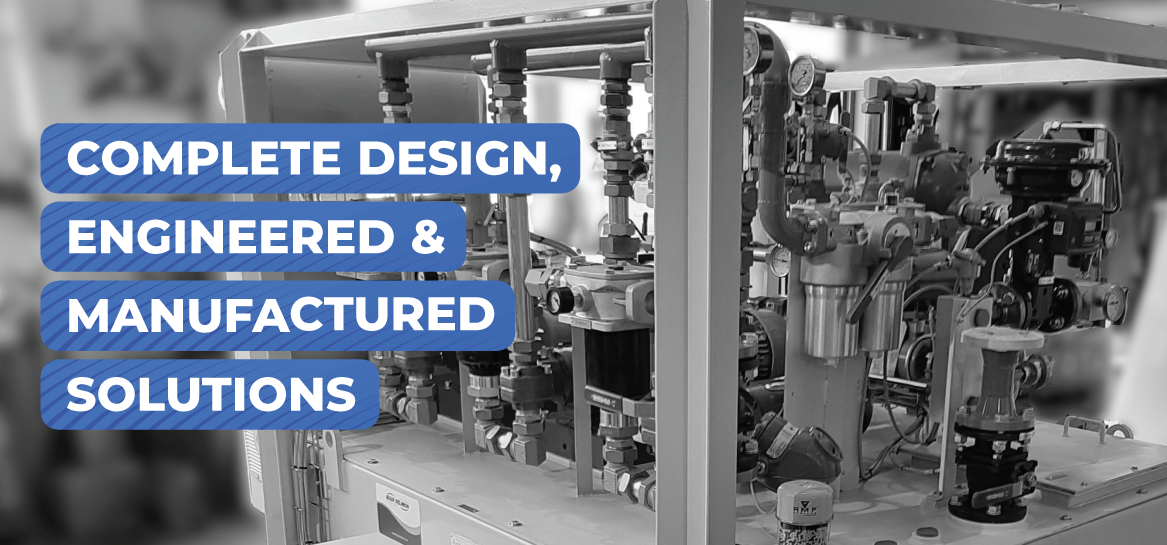

COMPLETE DESIGN SOLUTIONS

We pride ourselves on our ability to deliver the complete engineered design solution. Using the latest CAD technology, our innovative design team works together to bring your specifications to life. Through the use of technical drawings, 2D and 3D modeling, our designers ensure all specifications are met with precision without ever compromising the systems efficiency or the manufacturing process. With over 70 years of commercial experience, our dedicated team can cater for any set-up requirements and will guide you every step of the way from concept through to completion.

Standard Product Offering

One electric gear pump draws oil from a reservoir and supplies the oil via check valves through a single or dual basket type filter to the delivery connection.

Standard Units Comprised of:

MADE TO ORDER SYSTEM DESIGN

ENGINEERING

In providing the key functions of an Oil Recirculation System, the system is built from primary equipment, as outlined below.

RESERVOIRS OR TANKS

To allow for settlement, de-aeration and heating with the ability to facilitate a change of lubricant at the appropriate interval. Tank materials are typically carbon steel or stainless steel, and sized based on system flow rate and application.

PUMPS

Normally gear or screw type, motor driven to ensure the correct amount of lubricant is delivered to the friction points. In some cases, standby pumps are provided as part of the integrated design. These can be electrical or shaft driven, dependent on the application.

HEATERS & COOLERS

To ensure the lubricant reaches the points of application at the required viscosity. The heaters can be tank mounted or inline electric. The coolers can be plate type or shell and tube with the medium being water or water/glycol. Air can also be utilized for cooling using a fan and radiator.

FILTRATION & STRAINING EQUIPMENT

To maintain the system cleanliness. Typical oil filters will be either simplex or duplex type in the delivery line, suction line strainers, return line strainers, and tank breather/filters.

JACKING OIL PANELS

Jacking Oil Panels produce a small flow rate of oil at high pressure to lift the shaft of a bearing before it starts to rotate. Typical applications are large generators, cement kilns and ball mills.

In addition to the main primary equipment, a number of optional system components can be included, depending on the customer specifications and technical requirements.

RESERVOIR LEVEL MONITORING

Visual indicators, electrical switches and/or transmitters to alert the operator of low or high oil level, and protect the pump and tank immersion heater(s) from operating when the oil level is too low.

PRESSURE MONITORING

Visual gauges, electrical switches and/or transmitters to alert the operator of low or high pressures in the oil system delivery circuit, and similar pressure differential instruments to monitor the pressure drop across the main supply filter.

TEMPERATURE MONITORING

Visual gauges, electrical switches and/or transmitters to monitor the reservoir and delivery line oil temperatures.

FLOW MONITORING

Visual indicators, electrical switches and/or transmitters to monitor the oil flow to the friction point(s), oil return to the reservoir and cooling water supply. To support this, Bijur Delimon has developed the DS405 Lubrication Monitor; a highly configurable product that can be used on Oil Recirculation Systems and Total Loss Oil or Grease Systems respectively. Oil Recirculation Systems are real-time monitoring of the flow rate of oil, typicaly through an oval gear flowmeter. Alternative vane or spring operated flow meters are available.

CONTROL VALVES

Pump relief valves to protect the pump against excessive back pressure, system pressure control valves to control the flow and pressure of the lubricant to the friction point(s), and temperature control valve to either modulate the water flow to the water/oil cooler or by-pass the cooler when fitting in the oil supply line when the oil does not require cooling.

ISOLATION VALVES / CHECK VALVES

To isolate the oil or water supply, and prevent the oil from returning to the reservoir.

AIR PRESSURE VESSELS

Used in large systems to ensure sufficient pressure exists in the system to provide lubrication to all application points during operation and run down of the parent machine in the event of a power cut.

RUN DOWN TANKS

To provide lubrication to all application points during run down of the parent machine in the event of a power cut.

RUN DOWN PUMP

Pump operating from DC voltages can be employed during run down.

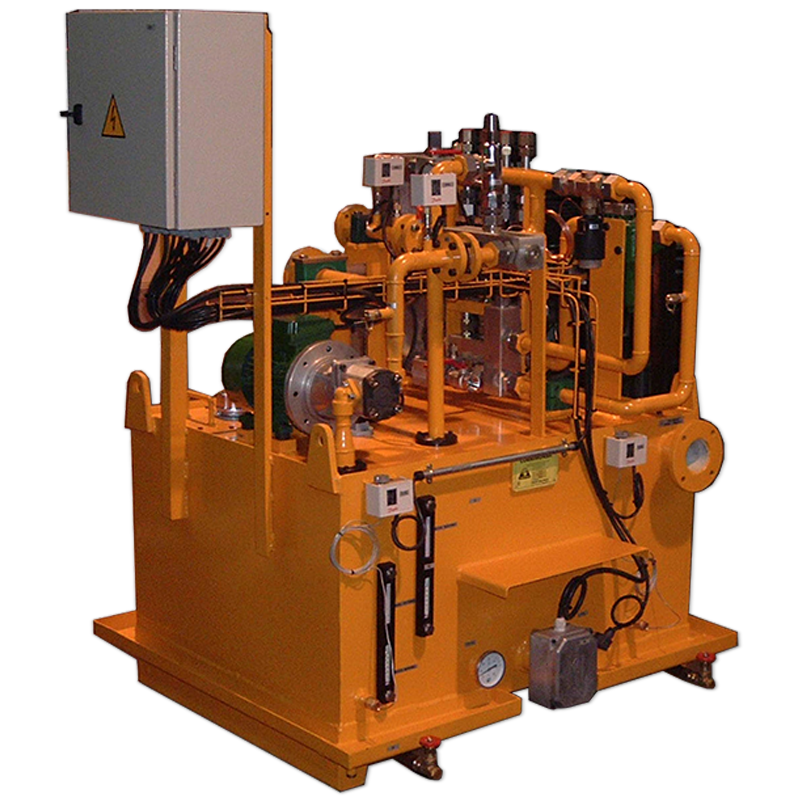

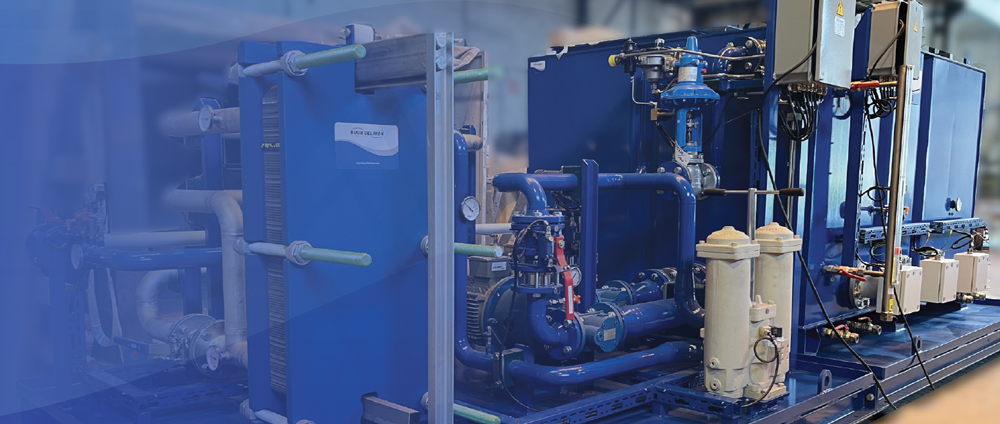

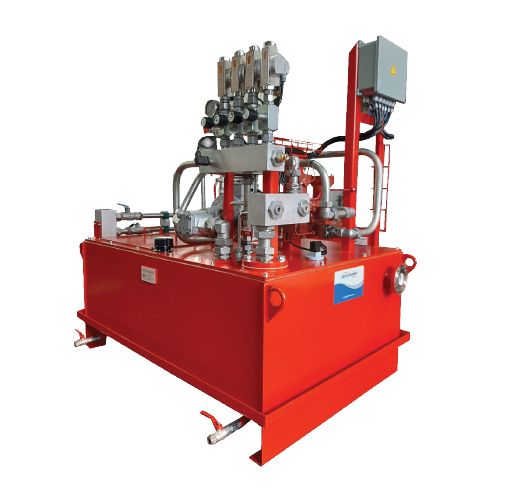

SMALL UNITS

MEDIUM UNITS

LARGE UNITS

MANUFACTURE

ELECTRICAL CONTROL PANEL ASSEMBLY

Our electrical engineering team are able to provide bespoke solutions for electrical. Design service from power supply to control panel and beyond. As standard, and if required, our systems are pre-wired at the factory.

SERVICES & SPARES

Maintaining Systems Throughout Their Lifetime

Bijur Delimon, either on a fixed contract or call-out basis, can maintain systems throughout their lifetime.

Our Service Department also operates contracts to provide labor to maintain plant in their client's works including system repairs, filling automatic grease systems, manual grease systems, manual greasing, and checking/filling oil reservoirs, gearboxes, etc.