LUBRICATION SOLUTIONS

PAPER MILLS

THE LUBRICATION

SOLUTION FOR

PAPER MILLS

Stationary equipment used in lumber and wood operations are exposed to tough environments including sawdust, moisture, heat, and continuous operation. In many mills, the operator is left to monitor machine lubrication, while also performing their normal duties. With an automatic lubrication system, the need for an operator to be within the work zone is eliminated, resulting in a safer work environment. Our system fully stands alone with on-board controls or ties in to your existing controls. By properly lubricating your bearings with a steady flow of lubricant, the bearings are kept cool, which reduces the risk of fire. Improve your mill production up-time and increase profits with an automatic lubrication system.

Need help implementing an automatic system?

Automatic Grease Lubrication

Automatic Grease Lubrication

M2500G Divider Block

M2500G Series Divider Valve Manifolds are the principal components of a progressive lubricating system. Modular construction makes these blocks easy to install, modify and maintain, without removing any tubing. The Zinc-Nickel plated steel body ensures longer life in nasty environments.

FL Injectors

FL injectors are positive displacement grease dispensing valves. Viton O-rings are standard to protect against high heat and synthetic lubricants. The injectors are interchangeable with major competitive brands. They come available in standard or 300 series stainless steel.

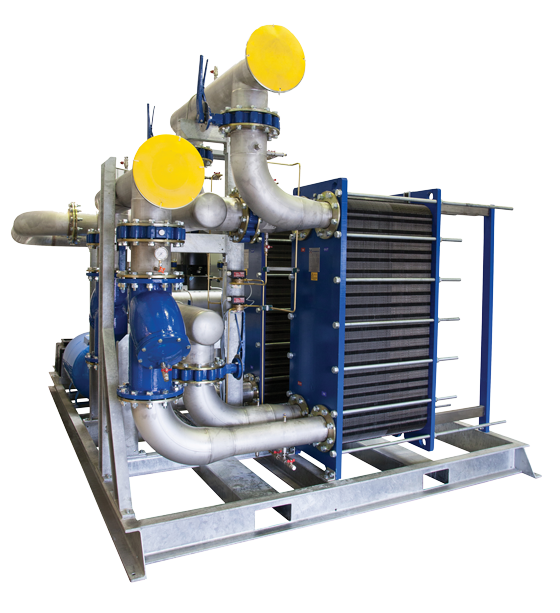

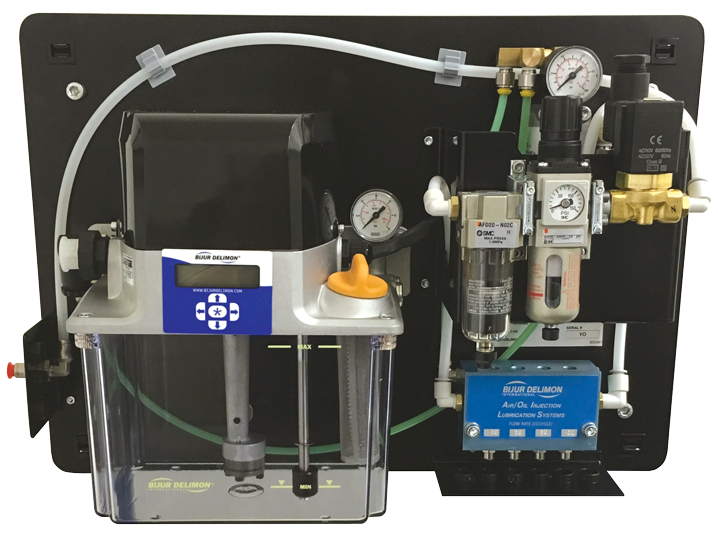

Circulating Oil Systems

Circulating Oil Systems