LUBRICATION SOLUTIONS

Wastewater

Treatment Plant

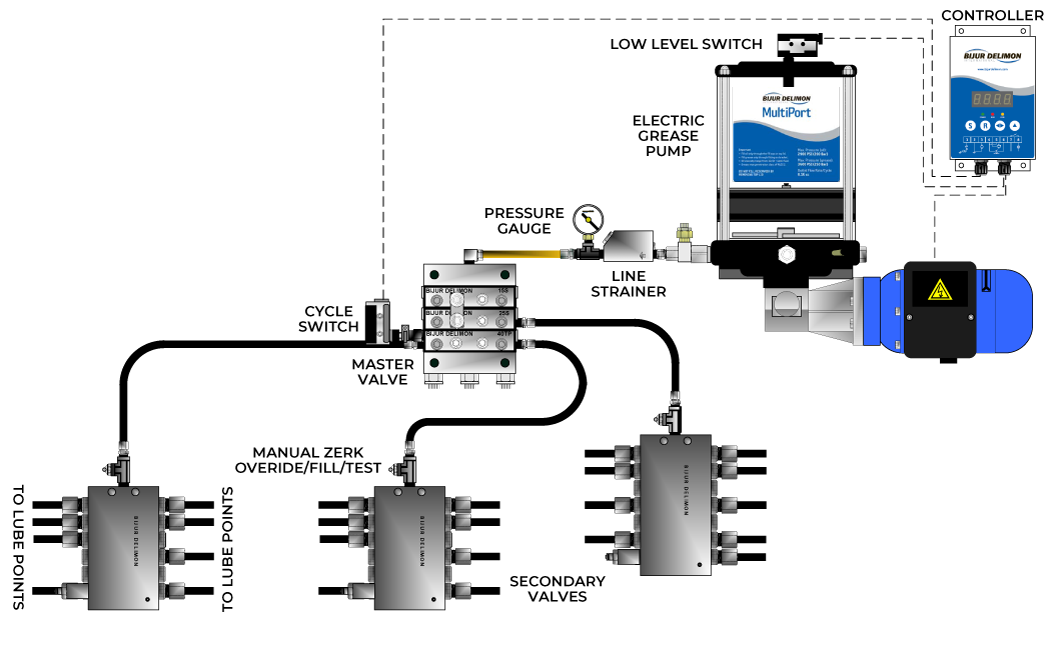

Stationary equipment used in wastewater treatment operations are exposed to tough environments including water, weather, chemicals and continuous operation. Utilizing automatic lubrication increases uptime by protecting bearings and other components. A Bijur Delimon system can prevent corrosion in equipment that is exposed to outside elements by preventing water from forming in the bearing. With our automatic lubrication system, no sophisticated controls are required. The system fully stands alone with on-board controls or ties in to your existing controls. Improve wastewater treatment plant performance and increase profits with the use of an automatic lubrication system.

Need a system designed for your application?

Dynamis Maxx Lubricator

Dynamis Maxx Lubricators are electrically driven piston pumps designed for use with series progressive systems. These lubricators can be fitted with up to three independent or combined piston elements providing positive displacement output to series progressive divider valves. Dynamis Maxx Lubricators are available with an integral pCo programmable controller, low level switch and various reservoir capacities. Operating voltages are 12 or 24 VDC.

M2500G Valve

M2500G Series Divider Valve Manifolds are the principal components of a progressive lubricating system. Modular construction makes these blocks easy to install, modify and maintain, without removing any tubing. The Zinc-Nickel plated steel body ensures longer life in nasty environments.