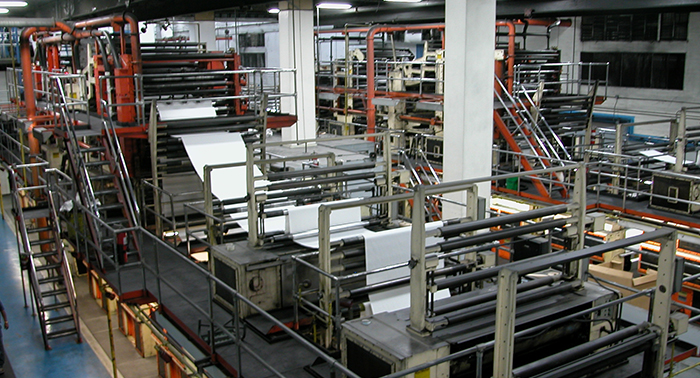

LUBRICATION SOLUTIONS

PRINTING PRESSES

THE LUBRICATION

SOLUTION FOR

PRINTING PRESSES

An automatic lubrication system provides the proper amount of lubricant at the right time for optimum reliability. Having a continuous delivery of lubricant maintains a hydro-dynamic lubricant film which reduces friction and wear. Replacing a bearing is costly and leads to unexpected downtime, but with a monitored system you can be alerted of a block or leak before it becomes a large problem. We offer optional monitoring for every bearing that detects any block or leak before critical bearings are affected. An automatic system that protects your bearings against wear, brings you peace of mind and eliminates the machine downtime that is associated with manual lubrication.

Need help implementing an automatic system?

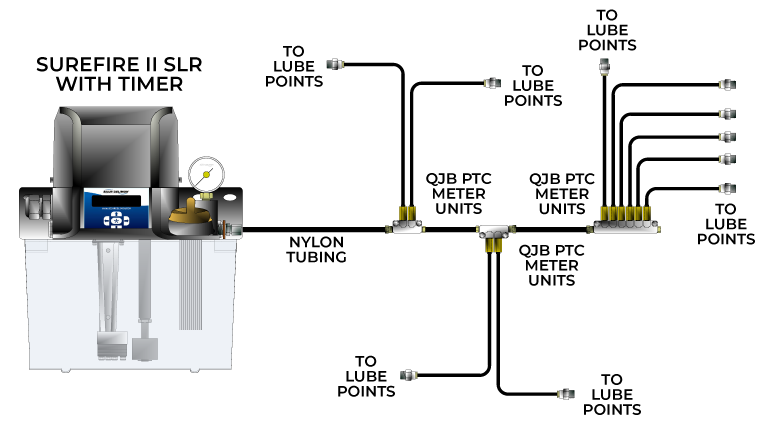

PRINTING PRESS SYSTEM DESIGN

PRINTING PRESS

SYSTEM DESIGN

SureFire II Lubricator

The SureFire II Lubricator is an automatic, robust and durable pump. Its compact size is designed to fit your space requirements and lubrication demands. The SureFire II Lubricator is a self-contained electric motor-driven gear pump that can adapt to a broad range of production machinery. The PDI version can handle oil or fluid grease for single injectors or injector groups serving up to 100 lubrication points. The SLR version uses oil to supply resistance fittings or resistance fittings groups serving up to 100 lubrication points. The SureFire pump’s versatility also allows it to perform with other lubrication system types and multiple applications.