LUBRICATION SOLUTIONS

Improve Centrifuge Performance

Using an automatic lubrication system prolongs the life of your centrifuge by ensuring your centrifuge equipment is protected from wear. The breakdown of essential components leads to unplanned downtime and costly repairs. Our lubrication systems deliver a precise amount of lubricant to necessary lube points, which eliminates over-lubrication and waste. By adding a Bijur Delimon lubrication system, your equipment is safely and continuously supplied lubricant while your equipment stays running.

Need a system designed for your application?

AUTOMATIC AIR/OIL LUBRICATION FOR THE ROTATING BOWL

AirMax

The AirMax is a simple economical lubricator, ideally suitable for air-oil systems. The AirMax is supplied with a 4 liter reservoir, pressure gauge, low level switch and oil inlet filter with the options of a oil pressure switch, solenoid valve and timer. The AirMax comes complete with a pumping unit and a integrated air-oil injection system. The required number of oil injectors and the delivery on each port can be selected from the smart number. The AirMax includes an air actuated, spring return piston pump. The inlet air pressure supply to the pumping element determines the output oil pressure. When used with positive displacement injectors (PDI) the minimum oil pressure should be 260 PSI (18 bar).

AUTOMATIC GREASE LUBRICATION FOR THE SUPPORT BEARINGS

Stationary equipment is exposed to tough environments including water, weather, chemicals, and continuous operation. Utilizing automatic lubrication increases uptime by protecting bearings and other components.

Automatic lubrication can prevent corrosion in equipment exposed to outside elements by preventing water from forming in the bearing.

An automatic lubrication system allows you to lubricate your equipment while it is running and increase safety by eliminating the need for operators to be within the work zone.

Featured Products

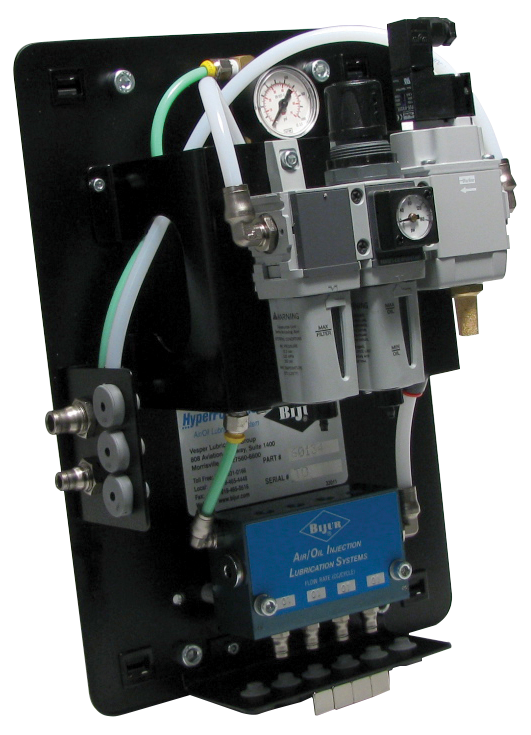

Oil Streak Generator Panel

The Air-Oil Generating Unit is a self contained lubricating system pre-assembled and ready for installation. The unit contains the following elements: an electric SureFire II Lubricator with precision gear oil pump, proprietary electronic controller to operate and monitor all functions, Air Treatment System (primary 5 micron filter and a secondary 0.01 micron coalescing filter), On-off Air Solenoid and an Air-Oil mixing manifold to inject oil into the air delivery tubing.

PVBM Divider Valve

PVB Mobile Divider Valves accurately meter and dispense lubricant to as many as 20 outlet lines at operating pressures up to 3600 psi (248 bar). Output volumes are fixed at 0.17cc (0.01 cu. in.) per cycle but can be combined with other outlets by using appropriate fittings for larger outputs. Valves are available with cycle indicator pins to provide visual confirmation of system operation. In addition the cycle pin can be fitted with a switch to provide electrical feedback to a system controller.

MultiPort II Lubricator

The MultiPort II Lubricator is an electrically driven multiple outlet lubrication unit designed primarily for use with progressive divider valve systems to accurately control the amount of grease and to monitor system performance via an integral controller.

Keep your equipment running efficiently during the most critical time of the year.

Keep your equipment running efficiently during the most critical time of the year.