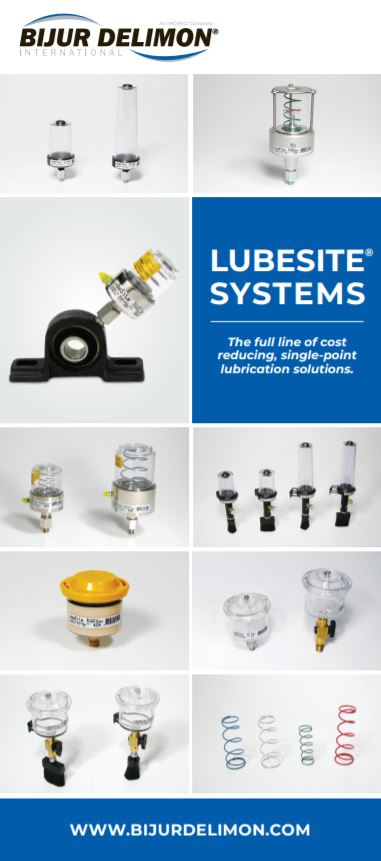

Single Point Lubrication Systems

Single-point lubricators are simple in design, but very effective at delivering grease or oil to your bearing lubrication point. By using different springs, users are able to estimate the time it will take to run the unit to empty. The on-demand technology makes it impossible to predict the exact date, but the clear reservoirs make it easy to visually assess the lubricant level at any time. Once the reservoir is filled and the unit is connected to a bearing, the single-point lubricator uses Venturi action to discharge lubricant only when the bearing is in motion. This benefits manufacturers that will have some planned machine downtime, because over-lubrication is eliminated. Because the single-point lubricator only generates 1-5 psi it will not blow bearing seals. Lubricant discharge is immediate when the vacuum is created from the bearing.

Environmentally-minded manufacturers will appreciate the refillable feature of these single-point lubricators, since the unit can remain mounted on a bearing, with just pennies of grease to top off the reservoir. And any grease can be used in these units, so grease used in other applications on the plant floor can be used.

APPLICATIONS

LubeSite automatic lubricators can be used on any equipment that has:

BENEFITS

Save

Money

Almost half of all bearing failure are due to improper lubrication. Over- and/or under-greasing causes the majority of problems. The major advantages of using a LubeSite product are:

Precise

Lubrication

Manual greasing with a grease gun is a method of lubrication determined by an estimate of the amount of grease used. The fact is, there is no accurate way to know when a bearing is getting too little or too much grease. The variables are endless.

Protect

Personnel

LubeSite units often permit longer periods between greasing, allowing your personnel to avoid lubricating while equipment is operating.

The transparent reservoir permits a visual inspection of grease level from a safe distance whenever lubrication is required in a hazardous or hard-to-reach location.

INDUSTRIES SERVED

LubeSite is used in the following industries:

LubeSite 200 Series

Polycarbonate Base

LubeSite 200 Series feature a clear, polycarbonate reservoir and base. This design allows for a visual inspection of the unit's internal workings. The 200 Series units should be specified for applications with minimal vibration, impact, shock, high-torque, or centrifugal forces. All units are assembled with medium springs (light and heavy springs are included in each box). An extra heavy (orange) spring is available for applications requiring the use of an extension or for higher pressure flushing applications.

LubeSite 300 Series

Metal Base

LubeSite 300 Series are designed for applications subject to vibration, impact, shock, high-torque, or centrifugal forces. All units are assembled with medium springs (light and heavy springs are included in each box). An extra heavy (orange) spring is available for applications requiring the use of an extension or for higher pressure flushing applications.

LubeSite 500 Series

Corrosion Resistant, Metal Base

LubeSite 500 Series are nickel-chrome, double-plated for applications where corrosive resistance is required, such as chemical and food processing applications. All units are assembled with medium springs (light and heavy springs are included in each box). An extra heavy (orange) spring is available for applications requiring the use of an extension or for higher pressure flushing applications. The piston seal ring is fabricated from chemical-resistant Viton®.

LubeSite 704

High Temperature, Metal Base

LubeSite 704 allows precise dispensing of grease to a bearing in ambient temperatures up to 450°F (232°C). It's ideal for applications in steel mills, foundries, lumber drying kilns, glass plants, nuclear environments, and metal heat-treating facilities.

The refillable, transparent reservoir permits a visual inspection of grease level at a safe distance. This feature is especially important in high temperature applications.

Overview

To dependably fill the need for automatic oil lubricaiton, we offer a full line of LubeSite single-point oilers, which include:

Our popular standard oiler offers the flexibility of a 4 oz. or an 8 oz. capacity reservoir set in a metal base. This base will withstand the punishment of extreme vibration or industry's worst environments.

These automatic oilers provide precise oil lubrication for machine tools, oil-lubricated bearings, gear boxes, motors, drives, and chains. LubeSite oil lubricators feature a poke-through cap allowing refill by standard oil can. The hole then closes to prevent contamination.

Features

LubeSite Drip Oilers

Drip feed oilers are perhaps the most popular method of automatic oil lubrication. The lubricant feed rate can be set by the operator by merely turning the needle valve and viewing the drip rate in the flow sight. Oil flow can be stopped simply by shutting the valve.

A cam-lock valve flow sight is also available with drip oilers as an alternative method for precise metering applications. They have a durable polycarbonate flow sight, which is a major improvement over the breakable glass sights currently used in other drip oilers. These valves may be purchased separately.

LubeSite Gravity Feed Oilers

These single-point lubricators maintain a constant flow to oil-lubricated bearings. The durable polycarbonate reservoir makes these oilers desirable in applications, such as food processing plants, where there would be the danger of broken glass from oil-style oilers. These units can also be used as an oil level indicator, reserve reservoir, or for back-pressure relief on machine start-up.

LubeSite Chain Oilers

By adding a properly selected and applied chain oiler to your drive chain, you can greatly improve a drive's performance, operating life and efficiency.

As a chain moves in a sprocket, there is relative movement between the pin and bushing surfaces. Wear at these points creates elongation, decreasing both chain life and efficiency. By maintaining an oil film between the pin and bushing, you can greatly reduce this wear.

Proper lubrication can also help to prevent chain failure by providing protection against rust and corrosion. Rusting allows pits to form, causing stress concentration points, which can result in premature chain failure, even at reduced loads. The brush's bristles will also help to clean the chain by removing dirt and other contaminants while replacing them with clean oil.

LubeSite chain oilers automatically function at predetermined rates to prevent over- and under-lubrication. Downtime is eliminated in applicaitons where equipment must be shut down to get to the chain.

The most ideal positioning of LubeSite chain oilers is directly in front of the drive sprocket.

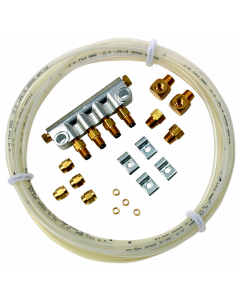

LubeLine™ Refill Kit

Remote Grease Refill Kit

The great majority of plants have hard to reach lubrication sites. The LubeLine Refill Kit allows refilling from distances up to 10 feet, and will fit all grease units.

The LubeLine™ Refill Kit comes complete with all of the required fittings and 10 feet of high pressure tube. Remember, this product is specifically designed to refill a LubeSite unit, not replace it. LubeLine™ units should be pre-filled prior to hook-up to the LubeSite unit. Be certain the LubeLine™ Refill kit is free of all air bubbles.

Denco Constant Level Oiler

The Denco Constant Level Oiler maintains a constant lubricant level in a bearing housing or gearbox automatically making up lubricant usage fmor its back-up reservoir.

Operation

The Denco Constant Level Oiler is based on the simple air compensation principal. As the oil level in the bearing falls, the level in the body of the oiler also falls. This fall in level uncovers the bottom of the chamfered feed tube of the oiler and air is admitted into the oil reservoir. An equivalent amount of oil is permitted to escape from the reservoir down the oil feed tube to the body of the oiler, restoring the pre-set oil level and sealing off the air feed tube. This sequence is repeated whenever the level of the oil in the bearing or sump fall and will continue until the reservoir is empty.

Features

LubeSite Vented Liquid Level Sight

LubeSite's accurate way to check liquid level in a closed tank. Both male and female models feature a large window on two sides for easy visual inspection, top venting for vertical mounting and a sight tube, which is designed for easy cleaning.

LubeSite Adjustable Valve Flow Sight

This cam makes small flow adjustments easier. The lock nut resists vibrations and maintains a preset flow. It has an easy to see lock on/lock off action with spring action to positively control the needle.

-

TubingSKU: K1079Kit Tubing Service 5/32 Learn More

TubingSKU: K1079Kit Tubing Service 5/32 Learn More -

TubingSKU: 37704Kit LubeSite 200/300/500 Extension 6ft. Learn More

TubingSKU: 37704Kit LubeSite 200/300/500 Extension 6ft. Learn More -

LubeSiteSKU: RB-8 CAMChain Oiler Round Brush 8oz Cam Learn More

LubeSiteSKU: RB-8 CAMChain Oiler Round Brush 8oz Cam Learn More -

LubeSiteSKU: RB-8Chain Oiler Round Brush 8oz Learn More

LubeSiteSKU: RB-8Chain Oiler Round Brush 8oz Learn More -

LubeSiteSKU: RB-4 CAMChain Oiler Round Brush 4oz Cam Learn More

LubeSiteSKU: RB-4 CAMChain Oiler Round Brush 4oz Cam Learn More -

LubeSiteSKU: RB-4Chain Oiler Round Brush 4oz Learn More

LubeSiteSKU: RB-4Chain Oiler Round Brush 4oz Learn More -

LubeSiteSKU: FB-8 CAMChain Oiler Flat Brush 8oz Cam Learn More

LubeSiteSKU: FB-8 CAMChain Oiler Flat Brush 8oz Cam Learn More -

LubeSiteSKU: FB-8Chain Oiler Flat Brush 8oz Learn More

LubeSiteSKU: FB-8Chain Oiler Flat Brush 8oz Learn More -

LubeSiteSKU: FB-4 CAMChain Oiler Flat Brush 4oz Cam Learn More

LubeSiteSKU: FB-4 CAMChain Oiler Flat Brush 4oz Cam Learn More -

LubeSiteSKU: FB-4Chain Oiler Flat Brush 4oz Learn More

LubeSiteSKU: FB-4Chain Oiler Flat Brush 4oz Learn More -

LubeSiteSKU: 803-11Flat Brush 1/8NPTM Learn More

LubeSiteSKU: 803-11Flat Brush 1/8NPTM Learn More -

LubeSiteSKU: 803-10Round Brush 1/8NPTM Learn More

LubeSiteSKU: 803-10Round Brush 1/8NPTM Learn More