Understanding Lubrication Management

Lubrication management makes up a large part of on-going equipment maintainance. Proper lubrication of critical components is essential because it leads to equipment that has a longer lifetime and reduced downtime. Equipment can be lubricated either manually or automatically. A manual lubrication program involves stopping work to do lubrication maintenance to your machine. This can bring about inconsistent grease levels, wasted lubricant, and safety issues for employees carrying out the maintenance duties. An automatic lubrication system allows you to lubricate your machine while it is in operation, which increases productivity and keeps your business running smoothly.

Optimal Lubrication

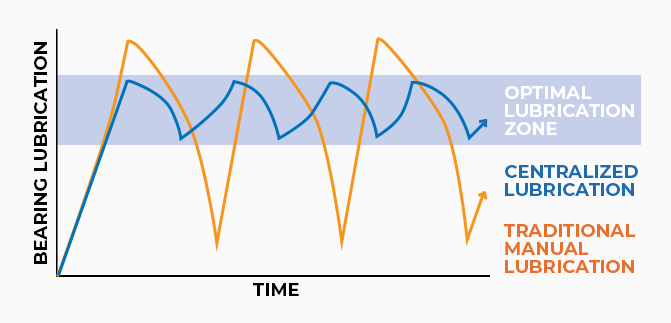

A manual lubrication program will inevitably result in "feast or famine" conditions for your equipment's components.

Automatic lubrication ends this cycle by applying small amounts of lubricant frequently while the equipment is running. This keeps your machine in the "Optimal Lubrication Zone."

Why Do Companies Choose to Manually Lubricate?

The average cost to manually lubricate a mid-size loader is over $15,000 a year! (Assumes 30 minutes labor/day at $30/hr and $95/hr of lost production.)

Visual inspection is critical whether you are lubricating manually or automatically. With automatic lubrication your operator can spend more time looking for equipment issues and less time searching for all the points needing lubrication.

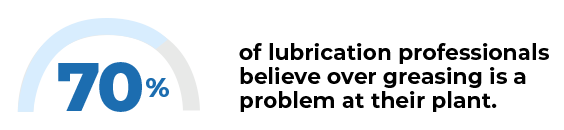

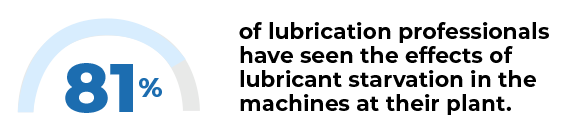

The vast majority of lubrication professionals admit they over and under lubricate their equipment. Either of these conditions will cause problems both immediately and long term.

Dangers of Over Greasing

Dangers of Lubricant Starvation

Challenges and Costs

of Manual Lubrication

Why is it a Challenge to Manually Lubricate Construction Equipment?

What are the Costs of Poor Manual Lubrication?

REQUEST

A QUOTE

Need help implementing an automatic system?

LUBRICATION

PRODUCTS

Shop our full catalog of products.

REQUEST

A QUOTE

Need help implementing an automatic system?

LUBRICATION

PRODUCTS

Shop our full catalog of products.