LUBRICATION SOLUTIONS

Wind Turbine

Heights and strong winds make maintaining wind turbines demanding and specialized work. A wind turbine lubrication system from Bijur Delimon is built to increase the time between turbine maintenance visits to eight to twelve months. We have developed a lubricating system kit for use on wind turbines and windmills, which is tested as a system before shipment. Many kits include prefilled grease lines and even prefilled reservoirs straight from our factory, helping you to avoid using a substitute grease that is not suitable. With lubricating systems on wind turbines in the US, Canada, and Brazil, Bijur Delimon has become a leader in providing automatic lubrication systems to the wind energy industry.

Need a system designed for your application?

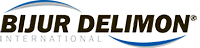

WIND ENERGY APPLICATIONS

Proactive Lubrication Maintenance

Wind turbines experience wear and tear from severe environmental factors and structural and mechanical failures, which contribute to the essential need for a proactive lubrication maintenance program. For a reliable wind turbine, many lubrication points are critical to maintain, including the gearbox, generator bearing, open gear, pitch gear, pitch bearing, rotor shaft, yaw bearing, yaw gear, and the hydraulic systems.

WIND TURBINE SYSTEM DESIGN

MultiPort II Lubricator Pump

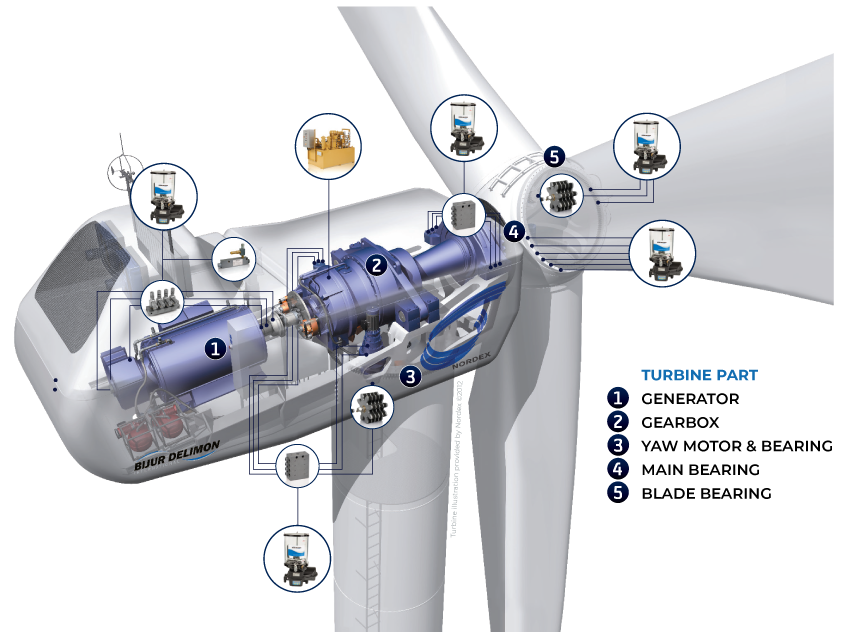

Gear Pinion

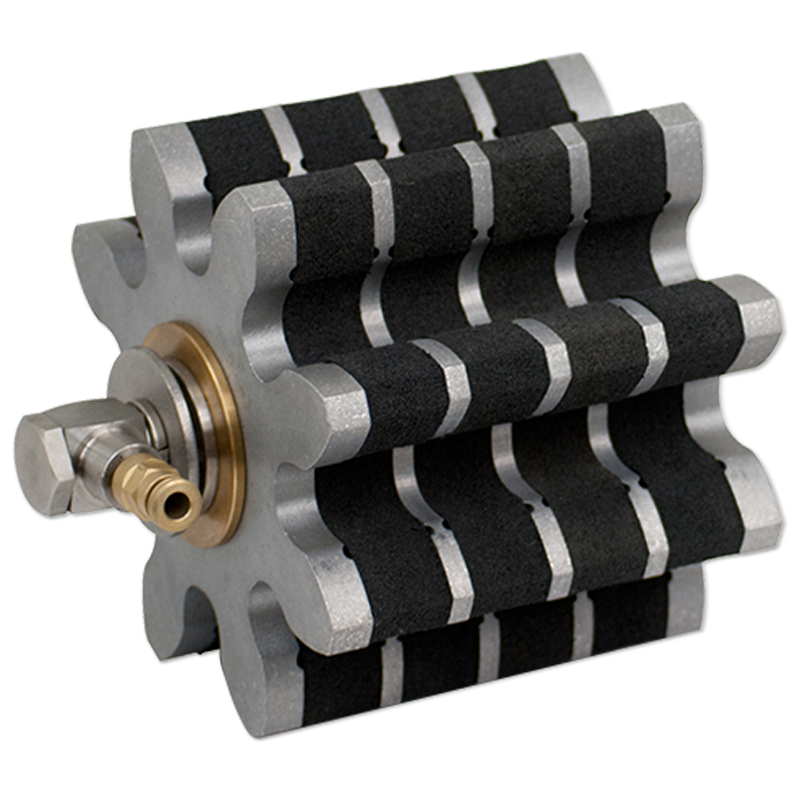

Suction Element SLE

CXL2 Injectors