LUBRICATION SOLUTIONS

OFFSET PRINTING PRESSES

THE LUBRICATION

SOLUTION FOR

OFFSET PRINTING PRESSES

An automatic lubrication system provides the proper amount of lubricant at the right time for optimum reliability. Having a continuous delivery of lubricant maintains a hydro-dynamic lubricant film which reduces friction and wear. Replacing a bearing is costly and leads to unexpected downtime, but with a monitored system you can be alerted of a block or leak before it becomes a large problem. We offer optional monitoring for every bearing that detects any block or leak before critical bearings are affected. An automatic system that protects your bearings against wear, brings you peace of mind and eliminates the machine downtime that is associated with manual lubrication.

Need help implementing an automatic system?

OFFSET PRINTING PRESS SYSTEM DESIGN

OFFSET PRINTING PRESS

SYSTEM DESIGN

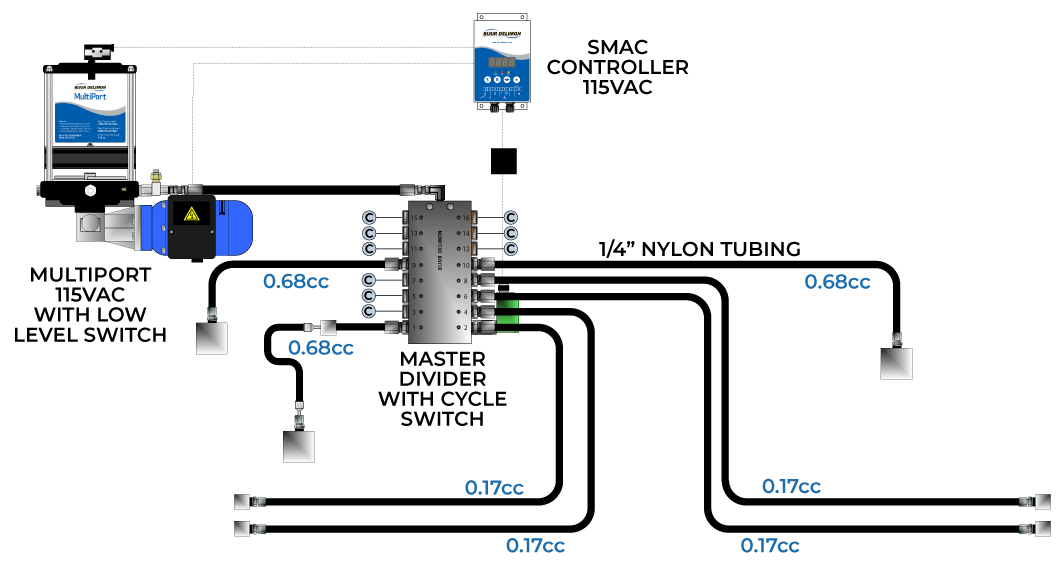

MultiPort II Lubricator

The MultiPort II Lubricator is an electrically driven multiple outlet lubrication unit designed primarily for use with progressive divider valve systems to accurately control the amount of grease and to monitor system performance via an integral controller.

PVBM Progressive Divider Valve

The corrosion resistant PVBM Divider Valve dispenses lubricant to as many as 20 outlet lines at operating pressures up to 3600 psi. This compact valve can be located near the lube points to accurately dispense grease automatically to the entire machine. Valves are available with cycle indicator pins to provide visual confirmation of system operation. In addition, the cycle pin can be fitted with a switch to provide electrical feedback to a system controller.

M2500G Divider Block

M2500G Series of progressive divider valves are at the heart of many single line centralized lubrication systems. Modular construction makes the system easy to install, modify and maintain without tube disassembly. Valve operation can be monitored utilizing a single indicator switch.