LUBRICATION SOLUTIONS

HIGH SPEED SPINDLES

Bijur Delimon has partnered with some of the largest machine tool makers in the history of the industry. The expertise we have gained working with these OEMs has helped us compile a product range that fits what the machine tool industry demands. From automatic and manual pumps to meter units and adjustable injectors, Bijur Delimon has the total package.

Not only do we manufacture products that have been tried and tested in the field, we have a capable support team ready to assist you.

Need help implementing an automatic system?

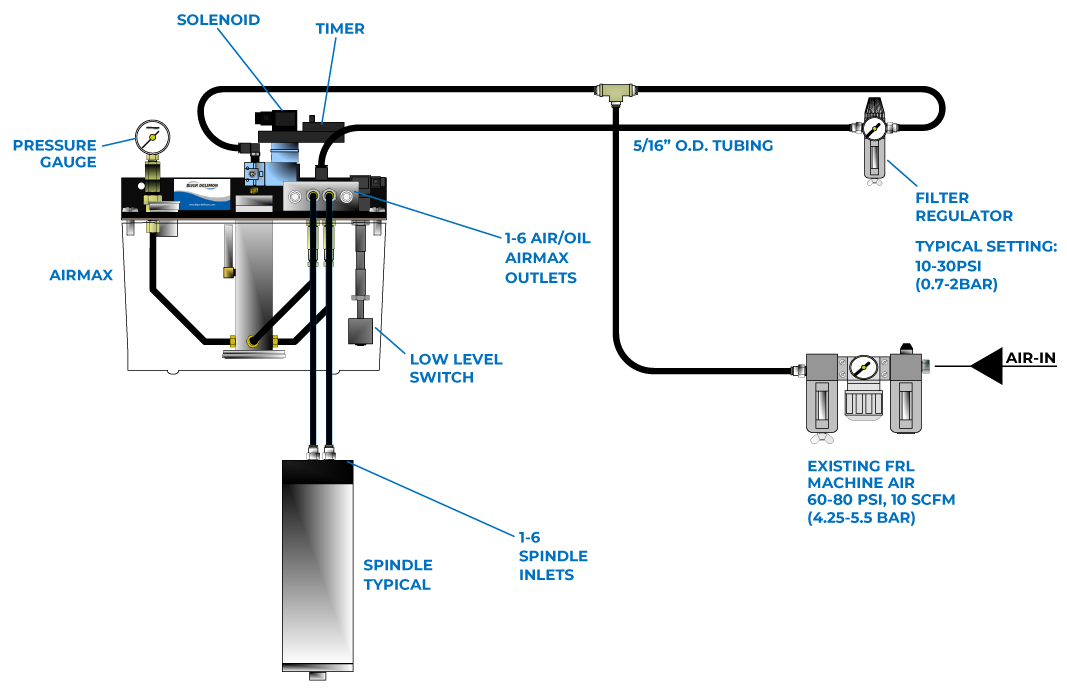

Air-Oil Lubrication System for High Speed Spindle Applications

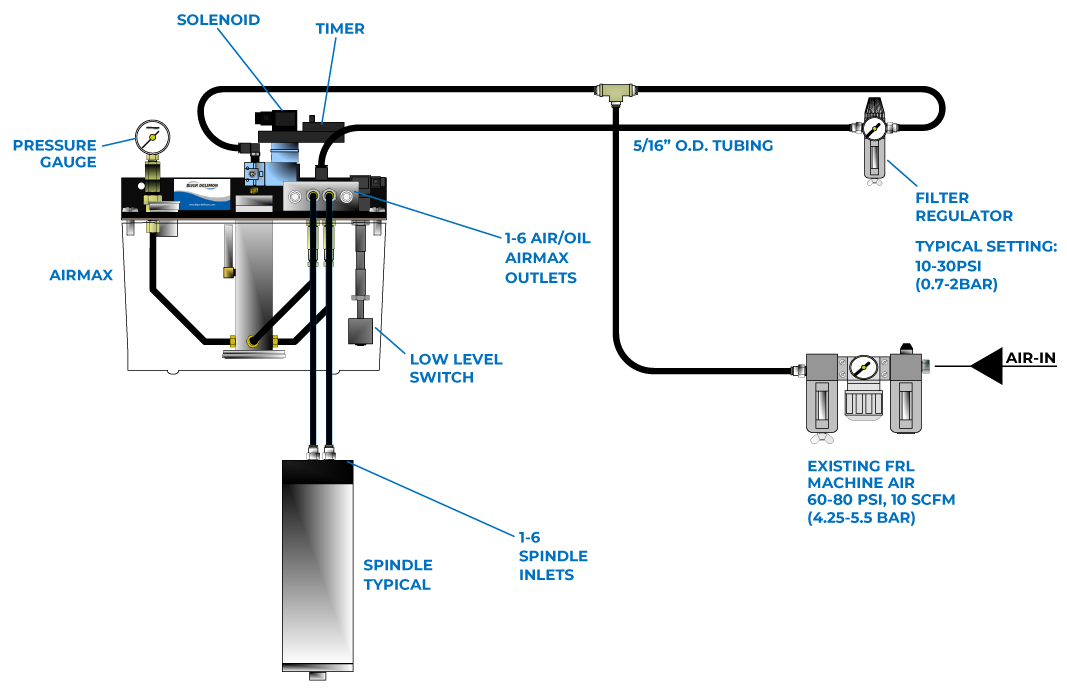

AirMax Pneumatic Pump

The AirMax is a simple economical lubricator, ideally suitable for air-oil systems. The AirMax is supplied with a 3-liter reservoir, pressure gauge and oil inlet filter with the options of a oil pressure switch, low level switch, solenoid valve, and timer.

The AirMax comes complete with a pumping unit and an integrated air-oil injection system. The required number of oil injectors and the delivery on each port can be selected from the smart number.

The AirMax includes an air actuated, spring return piston pump. The inlet air pressure supply to the pumping element determines the output oil pressure. When used with positive displacement injectors (PDI) the minimum oil pressure should be 260 psi (18 bar).

For extended service, incoming air must be dry. Always use a suitable FRL unit (filter/regulator lubricator) to control the inlet air supply to the pumping unit (set air to recommended operating pressure). The AirMax pumping unit is cycled using a 3/2-way solenoid valve (typical cycle: 5 seconds "on" and 30-300 seconds "off").

A continuous air supply is required to the air-oil injection block and it should be separately regulated to control the air-oil flow rate to the lube point.