LUBRICATION SOLUTIONS

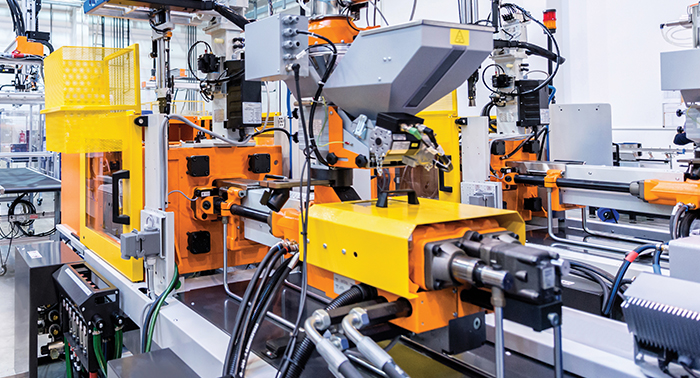

PLASTIC INJECTION MOLDING - OIL

As demand at manufacturing factories grows, the need for increased reliability and less downtime rises. Adding a lubrication system from Bijur Delimon increases your equipment life by decreasing the wear on vital components. An automatic lubrication system keeps your machinery running at peak levels leading to minimized downtime and reduced maintenance costs. It is easy to replace an existing system and the hard to find spare parts and components, along with increased compatibility with competitor products. You can rely on the automatic system to deliver a precise and accurate supply of clean lubricant that is applied to the right place at the right time.

Need help implementing an automatic system?

SYSTEM DESIGN FOR

PLASTIC INJECTION MOLDING - OIL

SYSTEM DESIGN FOR PLASTIC INJECTION MOLDING - OIL

Please contact us for assistance in replacing your existing system or components. Immediate shipment of both inch and metric components from inventory are available for replacing most competitive brands.

Please contact us for assistance in replacing your existing system or components. Immediate shipment of both inch and metric components from inventory are available for replacing most competitive brands.

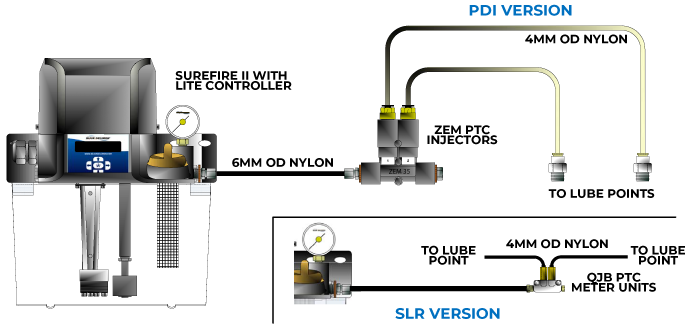

SureFire II

The SureFire II Lubricator is an automatic, robust and durable pump. Its compact size is designed to fit your space requirements and lubrication demands. The SureFire II Lubricator is a self-contained electric motor-driven gear pump that can adapt to a broad range of production machinery. The PDI version can handle oil or fluid grease for single injectors or injector groups serving up to 100 lubrication points. The SLR version uses oil to supply resistance fittings or resistance fittings groups serving up to 100 lubrication points. The SureFire pump’s versatility also allows it to perform with other lubrication system types and multiple applications.

ZEM Injectors

The ZEM Series injector line are positive displacement injectors (PDI) that deliver precise and controlled lubrication outputs which meet exact requirements for diverse applications. They are pre-fixed volumetric injectors that help ensure each lubrication point receives the proper amount of lubricant. Which means you won’t have to worry about over or under lubrication.