Dualine Lubrication Systems

Farval® Dualine lubricating systems are found in virtually every industry in which continuous duty operation is required. From steel production to pulp and paper, from mining equipment to machine tools, automatic application of the lubricant provides significant benefits to the equipment user. There are several components that are used in designing a Dualine lubrication system, including valves, lubricators, reversing valves, central stations, controllers, and spray systems.

VALVES

Measuring valves are the heart of Farval® Dualine lubrication systems. They are mounted close to the lubrication points and are hydraulically operated by pressure from the first and then the second of the two supply lines. On each pressurization cycle, they indirectly discharge fixed volumes of lubricant to the bearing or lubrication point.

LUBRICATORS

Manual, electric and pneumatic lubricators store and pump lubricant to Dualine valves throughout the system.

REVERSING VALVES

These valves change the flow and direction of pressure, which causes divider valves in the system to cycle.

CENTRAL STATIONS

Central stations include lubricator, cycle switch and reversing valve. Some versions are mounted on a plate for easier installation.

CONTROLLERS

Programmable give you access to key system functions, such as system on and off, and can control what happens when there is a problem in the system.

SPRAY SYSTEMS

Used to lubricate large gears and pinion sets.

REQUEST

A QUOTE

Need help implementing

a Dualine system?

View the Farval Dualine® Design Guide for a more in-depth look at planning and designing a dual line system.

REQUEST

A QUOTE

Need help implementing

an automatic system?

View the Farval Dualine® Design Guide for a more in-depth look at planning and designing a dual line system.

ADVANTAGES

FARVAL® DUALINE SYSTEMS

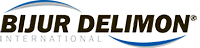

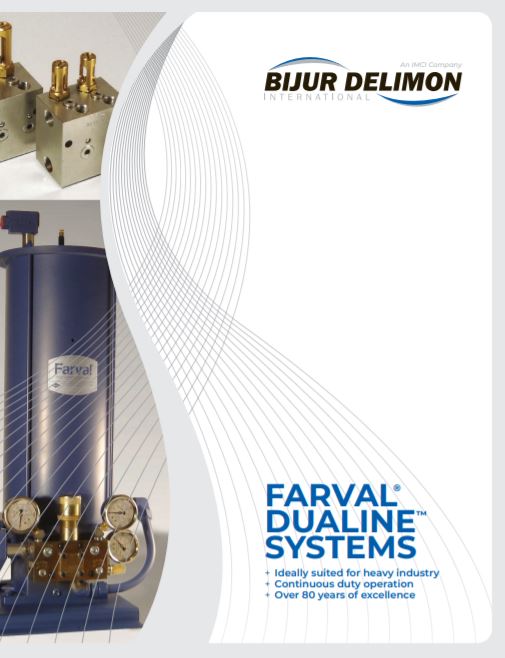

There are several various types of Farval® Dualine systems that can be designed using Bijur Delimon components. Flexibility is a key part of the Bijur Delimon product family. The following represent typical system layouts.

Motor Driven Piston Pump System

One of the most popular Farval® Dualine systems features Dualine valves, a central station (pump, cycle switch and reversing valve) and a controller.

Relevant products include:

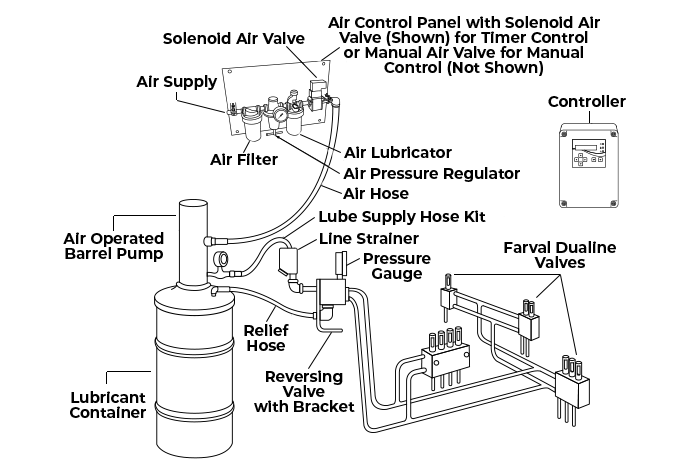

Air Powered System

Another popular Farval® Dualine system utilizes an air-operated barrel pump providing lubricant to Dualine valves in the system.

A reversing valve with a pressure gauge is utilized to reverse the lubrication flow in the system. A controller is also used to monitor system functionality.

Relevant products include:

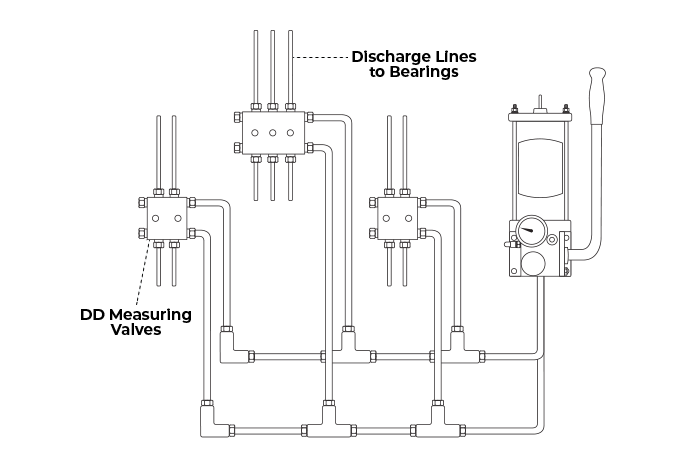

Manual Lubricator System

Bijur Delimon has a complete line of manual lubricators that can be affixed to DD, DM or DDM/SDM Dualine valves. The lubricators have a built-in reversing valve, so that pressure can be applied and released on each handle stroke.

Relevant products include:

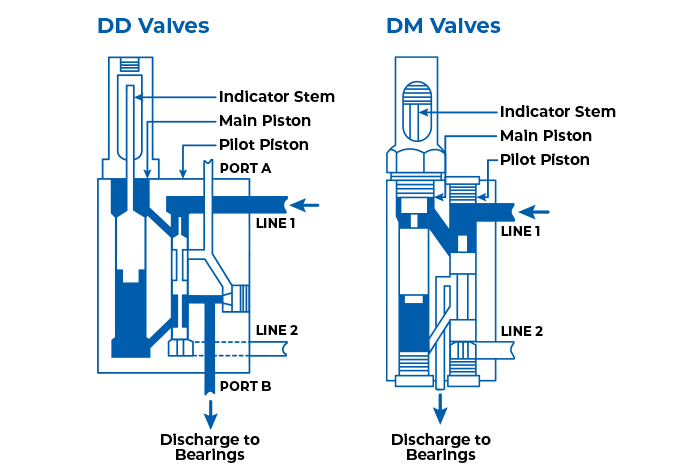

DD & DM Valves

Dualine DD and DM lubricating valves are completely hydraulic in operation and will deliver either oil or grease. They are also fully and individually adjustable in regard to discharge quantity and are equipped with operational indicators. Each DD valve serves two bearings; however, by a simple method of cross-porting, it will serve one. Therefore, a four valve block, as an example, can actually serve anywhere between four and eight bearings. DM series valves always have one discharge port per valve section located on the bottom of the valve. DD and DM valves can be supplied in several basic discharge capacities and are available in blocks consisting of one, two, three, or four valves.

Benefits

How it Works

Pressurized lubricant entering the valve forces the pilot piston down, allowing pressure to be applied to top of the main piston. The main piston beings to move down under pressure, forcing lubricant from its chamber, past the lower land of the pilot piston and out the discharge line to the bearing. When pressure in the supply line is reversed, lubricant then eneters valve and forces the pilot piston up, allowing pressure to be applied to bottom of main piston, which begins to move up, forcing lubricant from its chamber, past the upper land of the pilot piston and out the second discharge line to the bearing.

DDM & SDM Modular Valves

Dualine DDM and SDM lubricating valves have many advantages over traditional line mounted models. All working parts are in the module and these modules are fitted to base manifolds, which are permanently fitted to the centralized lubrication system. The double discharge module DDM feeds two lubrication points on alternative system cycles while the single discharge module SDM feeds a single lubrication point on each cycle.

A mixture of double and single discharge modules can be fited to each manifold either for assembly to serve an odd number of bearings or to give a greater lubricant quantity to selected points. Three sizes of modules can be supplied to cover a wide range of metered application volumes.

Benefits

DA Series Manual Lubricators

To support the successful operation of Dualine measuring valves and to ensure their performances, Bijur Delimon has designed equally rugged pumping units, which provide a dependable high-pressure source of lubricant supply.

For bearings that require an application of lubricant once or twice per shift, a manually-operated central pumping unit is used. These units consist of a double-acting piston pump, recirprocated by a hand lever through a rack-and-gear segment. A quick-fill connection provides a convenient means of filling the reservoir, and an inlet filter screen gives added protection against the entry of dirt. They may be located on the machine being lubricated or at any convenient point nearby. When the lubricant is oil, a float with oil level rod replaces the grease follower plate. Three sizes of reservoirs provide a supply of lubricant adequate for the number of bearings being lubricated.

Air-Operated Barrel Pumps

Air-operated barrel pumps are used where medium to heavy duty service conditions exist and rapid build-up of lubricating system pressure is desired in air-operated central stations.

In a Farval® Dualine lubricating system, the reversing valve directs pump flow to one of the two main supply lines while the second supply line is in relief to the pump reservoir. At the completion of each half lubrication cycle, the reversing valve redirects the pump and relief flow. Thus, on each succeeding half lubrication cycle, pressure and relief flow are alternated in the two main supply lines. This action causes the measuring valves to stroke and discharge lubricant to their respective bearingss. In an automatic system, the reversing valve also controls maximum system pressure and pump shut down.

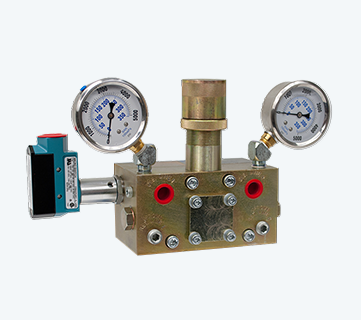

FR20

These reversing valves operate in conjunction with pressure switches. They control end-of-line systems (DC41 central stations and air powered systems).

DR4-5

These reversing valves are activated by system pressure and are adjustable between 500 and 3500 psi. They control non-return and return systems using CS2000, DC36 and DC42 central stations. They are also used with air barrel pumps for spray and medium and large Dualine systems.

SA-V

This reverse valve is designed for use in hydraulic Dualine systems. It can be used as a 4/2 or a 3/2 valve and is driven by a direct current geared motor.

Central stations store, control and supply the lubricant to Farval® Dualine systems. The major components are a motor, pump, reservoir, and reversing valve.

Central stations are available in 7 series: DPG, CS2000, DC36, DC41, DC42, BM-B, and BS-B. Each series offers a different capability in terms of type and quantity of lubricant, which can be handled and type of system that can be served. Each is available with motor and reservoir options and optional high or low level switches as indicated.

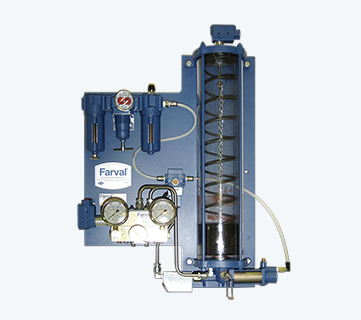

DPG

The DPG Pneumatic Lubricator is an air-operated recirprocating lubricator that discharges a fixed amount of lubricant into systems during a lubrication cycle. It includes a transparent reservoir with low level and spring loaded follower, reversing valve, grease strainer, FRL, air solenoid valve, and a filler fitting for refilling of reservoir.

CS2000

CS2000 stations store, control, and supply the lubricant to systems. Depending on reservoir size, they can be used in systems that service anything from small machine tools to large machinery in steel mills, or from small to large off-road machinery, such as power drills, power shovel and drag lines.

DC36

DC36 stations store, control, and supply lubricant to systems. The lubricant must be oil with a viscosity of not greater than 1900 SSU at 100°F. DC36 stations can be used in systems that service equipment requiring oil lubrication, such as machine tools and transfer equipment.

DC41 & DC42

DC41 and DC42 stations can supply either oil or grease to such installations as bar mills, billet mills, blast furnaces, and sintering machines. The two systems differ in the way they alternately pressurized and relieve (reverse) the two supply lines as well as in the way they control maximum system pressure and end the lubrication cycle. On DC41 systems, pressure is controlled by a pressure switch (one is installed in each line) that actuates the reversing valve (FR20) and stops the pump motor when system pressure rises to its setting. On DC42 systems, pressure is controlled by the reversing valve (DR45). The valve opens a micro switch, which stops the pump motor when system pressure rises to its setting. Timer controls for each type tailored to meet its specific requirements are available.

BM-B & BS-B

In applications where electricity is available to power the lubricator, our BM-B and BS-B models are ideally suited to be the heart of a lubrication system. These pumps are robust for harsh and severe applications and their compact construction of high-grade steel gives them a long service life. They are ideally suited to service medium- and large-sized machinery. They can also be used for refilling and mobile greasing systems. BM-B and BS-B lubricators do not ship with a reversing valve. The lubricators are valveless, positive displacement pumps consisting of a series of pistons actuated in a controlled suction and discharge action, producing a rugged, trouble-free lubricator.

SC400

The SC400 Multi-Function Controller/Monitor is designed to operate, control and monitor all types of Farval® Dualine systems, including those having an electric or hydraulic reversing valve. The unit is easily programmed by the customer via the controller's set-up mode.

The SC400 also allows customers to operate a two zone system with a single control. The SC400 has the ability to operate a pumpa nd two zone valves. Each zone operates independently. "Two zone" feature is not available for Dualine electric reversing valve systems or for systems that require "air purge" (afterblow).

The SC400 also incorporates an automatic fill feature. The SC400 activates a fill pump (as needed) to maintain proper fluid levels.

SMAC

The SMAC Controller is a multi-purpose programmable controller used with industrial lubrication systems. Controller settings are saved whenever power is interrupted. Up to four operating modes can be selected, which allows the controller to be used with various lubrication system designs. The controller is available in both 110 and 220/230 VAC service.

Features

Lube Point Monitor

The 55105 Lube Point Monitor is an accurate oval gear mechanism that incorporates two magnets into one of the nylon oval gears. The body incorporates a reed switch, which senses the magnet passing. Lubricant entering the monitor causes the gears to rotate. Each pulse equates to an approximate displacement of 0.040 cu. in. (.65cc). The monitoring of the 55105 is done with any PLC. The feedback from the monitor will assure that lubricant has reached the inlet of critical lubrication points.

Application

The Lube Point Monitor is intended to be mounted at or near the lubrication point inlet. It can be used with any type of grease or oil system (Dualine/Progressive/PDI). Due to the nature of the internals, proper filtration is required to keep contaminants out of the monitor body.

SPRAY SYSTEMS

Spray systems are used to lubricate large gears and pinion sets, such as those found on ball mills, rod mills, kiln, etc. Each system includes an air-operated pumping station, a measuring valve panel, a spray nozzle lance, and electrical controls.

Gear face width of 4" to 44" can be lubricated by nozzles with appropriate spacing on the spray lance. Since gear spray systems operate intermittently, they can be thought of as film maintaining devices. The electrical controls provide broad cycling flexbility as well as fault monitoring and afterblow to purge the nozzles.

Thirteen items are required to complete a Farval® Dualine spray system. The Spray Lance should be selected based on gear face width. The Valve Panel should be selected based on the number of spray nozzles required.

-

DA PumpSKU: DA6101AC6KG Dualine/Inj Learn More

DA PumpSKU: DA6101AC6KG Dualine/Inj Learn More -

DA PumpSKU: DA5101AC3KG Dualine/Inj Learn More

DA PumpSKU: DA5101AC3KG Dualine/Inj Learn More -

DA PumpSKU: DA4101AC2KG Dualine/Inj Learn More

DA PumpSKU: DA4101AC2KG Dualine/Inj Learn More -

CS2000 StationSKU: CS22101100lb Dualine LS HLS Learn More

CS2000 StationSKU: CS22101100lb Dualine LS HLS Learn More -

CS2000 StationSKU: CS22076GAL Dualine LS HLS Learn More

CS2000 StationSKU: CS22076GAL Dualine LS HLS Learn More -

CS2000 StationSKU: CS22066GAL Dualine LS Learn More

CS2000 StationSKU: CS22066GAL Dualine LS Learn More -

CS2000 StationSKU: CS222524lb. Dualine LS HLS Learn More

CS2000 StationSKU: CS222524lb. Dualine LS HLS Learn More -

CS2000 StationSKU: CS222424lb. Dualine LS Learn More

CS2000 StationSKU: CS222424lb. Dualine LS Learn More